Whether it’s simulation, visualization, or data bouncing back from the field, Big Data has entered the design process.

June 19, 2015

Thanks to Big Data, design teams can now receive feedback about product problems -- whether they occur on the factory production floor or during customer use. Much of this data has been around for years, though in the past it was less voluminous and harder to find. But now, data management has become part of the design engineer’s job function.

The top companies of the world, naturally, are leading the way in Big Data analytics for design and manufacturing. At Dell, data coming in from the field revealed memory problems with one of its business server problems that had not come to light in the design or production process. Dell was able to identify the source of the problem quickly through the use of Siemens’ Omneo data management system.

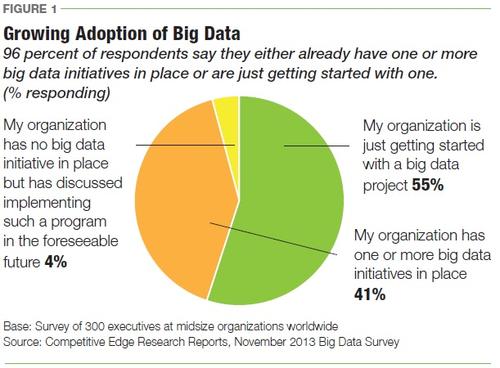

Ninety-one percent of companies are either already using Big Data or are getting started.

(Source: Competitive Edge Research)

MORE FROM DESIGN NEWS: Shooting for Industry 3.5

The system was used to diagnose the memory configuration problem, and it enabled Dell to get a replacement server out less than an hour after the customer reported a problem. “It would ordinarily take two weeks to identify the source of the problem and determine the fix, but they were able to get it done in two days,” said Bill Boswell, senior director of marketing and business strategy for Cloud Services at Siemens PLM. “The old manual way of approaching this would have required three days just to gather the data.”

The ability to identify and solve the problem quickly had a two-pronged benefit. “In this example, the problem would have resulted in missing an order cutoff date to the plant in China,” Boswell said. “The plant was shutting down for the holidays, so there would have been an additional delay of a week or more until the problem was solved. Dell realized the problem would impact more than just the one customer, so they pushed the solution to both the production and design stages.

Quality and efficiency are the reasons behind all the data collection. The whole point is to make better products while shortening time to market and reducing costs. The range of data that can help improve product quality can come from collecting information on product performance in the field as well as during the manufacturing process itself.

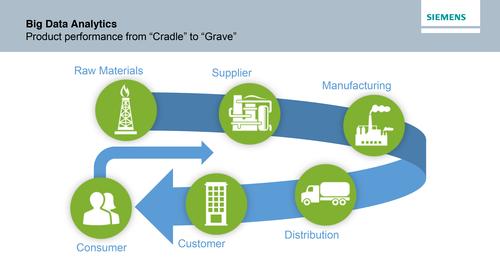

The closed loop of product data allows designers to see what the customer experiences.

(Source: Siemens PLM)

MORE FROM DESIGN NEWS: Siemens Juices Big Data Analytics with Omneo

“The most important thing in Big Data for design is product quality,” said Oleg Shilovitsky, a consultant who writes the blog BeyondPLM. “You are getting information about how the product is used by the customer. You can track how the product is performing, and that gives you a great opportunity to improve quality.”

Big Data can help the manufacturer uncover the source of a problem. “You can get data from the exact moment of failure, you can bring that together with other elements of data,” said Shilovitsky. “You discover what happened, and you find out if you may have a problem with a particular supplier or many suppliers. You can locate the problem’s specific circumstances and improve the quality of the product.”

“Manufacturing companies have a lot of data, from the manufacturing shop floor and from the products themselves,” Shilovitsky said. “Boeing gathers information from its aircraft. They’ve done it forever. GE gathers information on their turbines.”

About the Author(s)

You May Also Like