August 30, 2016

In the design stage of a product, you can create a digital twin of the product that can be tested and enhanced before an actual prototype is created. The automotive and aerospace industries are under intense pressure to produce extremely efficient products, so they're turning to design tools that can provide extensive simulation testing before a prototype is produced. These design tools have become critical for creating the next generation of clean cars and airplanes.

To support this effort, Siemens PLM has released a new iteration of its LMS Imagine.Lab software. The new version is designed for ease-of-use and compatibility with a wide range of simulation, CAE, and CAD tools. Also, to help companies meet environmental mandates, Imagine Lab now contains functions geared specifically to the automotive and aerospace industries to help them develop cleaner and more efficient products.

The tools that enhance the design of cars and planes can also be applied in other industries. "Our tools are based on the representation of the physics, and these physics can be applied to any system," Renaud Meillier, business development director simulation systems at Siemens PLM, told Design News. "The things we use for automotive can be reused for other industries."

Industry-Specific Functionality

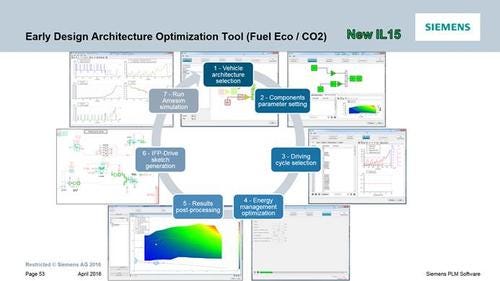

The new Imagine.Lab offers enhanced modeling capabilities to meet industry requirements resulting from environmental regulations, market changes, and economic constraints. A new set of interfaces enable faster parameterization and modeling to enable evaluation of the functional performance of vehicles or airplanes. Imagine.Lab attributes make it possible to design products right the first time in meeting expectations for the automotive, aerospace, heavy equipment, and mechanical industries. "The automotive mandates will be tough to meet. The simulated driving cycles vehicles need to pass have not been matched to real-life driving conditions," said Meillier. "So we created a tool that replicates actual driving cycles."

The previous simulation tools didn't model actual driving conditions that will be required to meet mandates. "In the past we developed it for straight roads, but our roads are not straight. So we included roads that simulate tracks for the car that are representative of real driving conditions," said Meillier. "During early design cycles of the product, there is a need to test new innovative architectures, whether it's hybrid or fuel cell. This helps our users to determine the best way to reduce energy consumption and emissions."

Your Plant. Smarter. Get informed on factory retrofitting, converging OT & IT, mastering cyber-physical transformation, predictive maintenance, 3DP in the factory, designing for maximum ROI and more in Industry 4.0: The Building Blocks of a Well-Oiled Smart Plant at Design & Manufacturing, Sept. 21-22, 2016 in Minneapolis. Register here for the event, hosted by Design News’ parent company, UBM.

Your Plant. Smarter. Get informed on factory retrofitting, converging OT & IT, mastering cyber-physical transformation, predictive maintenance, 3DP in the factory, designing for maximum ROI and more in Industry 4.0: The Building Blocks of a Well-Oiled Smart Plant at Design & Manufacturing, Sept. 21-22, 2016 in Minneapolis. Register here for the event, hosted by Design News’ parent company, UBM.

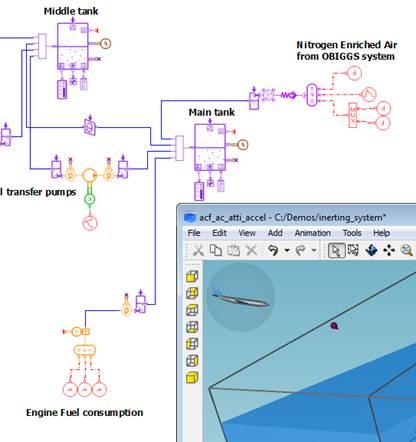

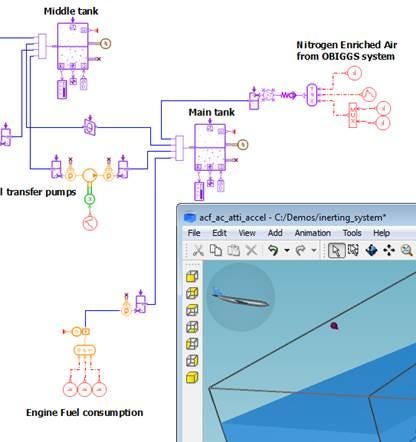

Siemens also developed dedicated tools to help the aerospace industry meet its environmental goals. "For aerospace, we're working on fuel consumption and emission, which requires fuel tank simulations that reveal how the fuel is consumed depending on the profile of the flight of the plane itself," said Meillier. "We also have dedicated solutions for jet engines so we can deal with fuel consumption and emissions. The aerospace mandates are not at the same level as the policies governing the automotive industry, but they're coming."

Ease of Use Advances

The new Imagine.Lab was designed to provide a smooth user experience through all phases of the design cycle. Siemens concentrated on enhancing workflow efficiency. The platform features improved modeling and analysis tools designed to help engineering departments develop better products faster and with higher quality. Interoperability has also been added to provide seamless integration of disparate models. "The new release has improved workflow efficiency," said Meillier. "We know that our customers want to save time by accessing simulation early in the lifecycle, long before the prototypes are created."

An additional goal of the new iteration was to make it easier to shift design tools. "We made a strong effort to improve the user friendliness in sketch aligning and automatically generating the model from the CAD," said Meillier. "With the CAD it can take a lengthy process to extract the model and do the simulation. So we've included some automation to help extract the data from the model and move it into the platform to help the user move quickly to creating simulation."

READ MORE ARTICLES ON DESIGN SOFTWARE:

Part of the process to simplify and speed the design process includes easy interoperability between design tools. "The openness capability of our platform is integrated in this release. That's important in an industry where there are many models created by many tools, using different software," said Meillier. "You don't have to convert the design to a different tool. You just export it into the platform."

[images via Siemens PLM]

Rob Spiegel has covered automation and control for 15 years, 12 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years he was owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like