December 9, 2011

CAD models can do many things and provide many levels of information about an emerging product design, but they really can't tell you anything about what it might cost to manufacture said design.

The latest release from aPriori, which bills itself as a product cost management tool provider, expands the system's costing capabilities and makes it easier to use those detailed cost estimates in multisite, enterprise deployments.

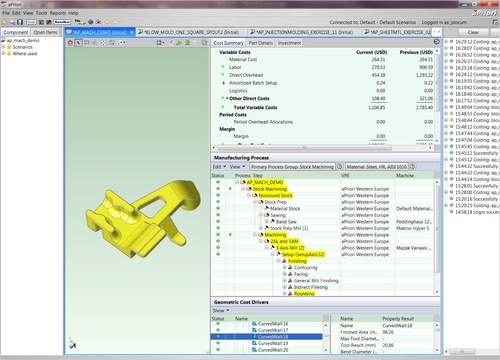

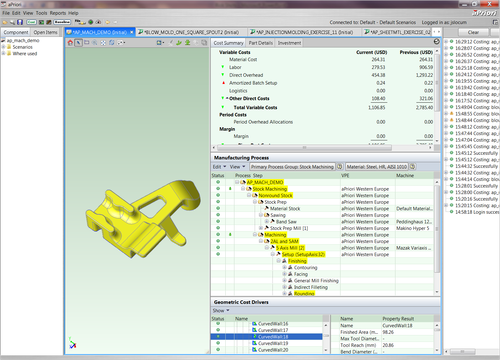

The aPriori tool is essentially a costing engine that precisely (and, officials say, instantly) determines the cost of a part or product directly from a CAD model, based on the materials to be used and the factory where it will be produced. The software is designed to help anyone in the product development process quickly understand and explore the implications of design tradeoffs on the cost of manufacturing the product. For example, if there's a change in the materials used, a product's structure is tweaked, or components are sourced from a different locale, users can input the data and have the software calculate the impact on the manufacturing costs.

This tie to CAD and the tool's geometry extraction capabilities are a big part of its story, officials told us. The tool can automatically extract properties from a CAD file. (It supports most of the popular products.) It can then populate the costing model with such parameters as radius, surface area, or number and structure of holes, unlike traditional costing solutions like spreadsheets or specialized tools, which require engineers, sourcing specialists, or tooling managers to enter a part's dimensions or characteristics manually.

Moreover, the software's other two components -- a routing engine, which is a set of rules and logic that determine how a geometry can be made, and the cost models, which crunch the numbers -- make it easier for noncosting experts to perform cost optimization analysis, according to Rick Burke, aPriori's vice president of marketing.

"A lot of systems don't have the routing engine, so a human provides input to the cost model, and that's where the need for an expert comes into play," Burke said. "Those tools can't tell you what is feasible or look at the geometry and say what is needed. Our routing engine automates this and provides input to the costing engine."

About the Author(s)

You May Also Like