December 10, 2015

In computer-aided engineering, we are seeing a vast number of advanced predictive modeling tools dedicated to solving specific engineering requirements and assisting engineers who are not experts in those disciplines. In acoustical analysis targeting noise-reduction in cars, Exa Corp. has been looking to give auto engineers tools to examine flow-induced noise sources such as greenhouse or underbody wind noise, HVAC and blower noise, and noise from within exhaust systems.

The company's PowerAcoustics and PowerFlow computational fluid dynamics analysis and simulation software are widely used in the design of automotive, aerospace, and rail systems, as well as other industries where noise reduction is crucial in order to meet customer or regulatory requirements. Exa says particularly that engineers have had difficulties unraveling complex turbulent air flows to home in on noise sources in HVAC systems which incorporate a blower, mixing unit, ducts, registers, and other elements.

Reducing the noise in HVAC systems is a high priority for automobile manufacturers right now, explained Dr. Franck Perot, senior director of acoustic applications at Exa, in an interview with Design News. "Engineers want to reduce the noise," he said, "but they can't see inside those systems to understand where the noise is produced. It's very difficult to improve the design if you don't know where the problem comes from."

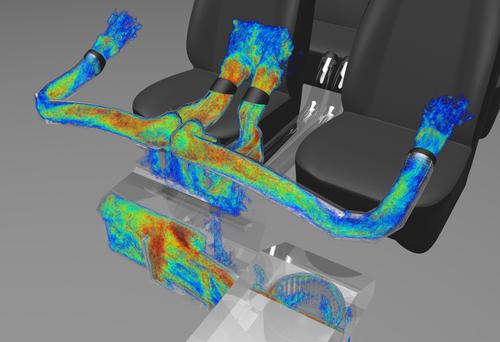

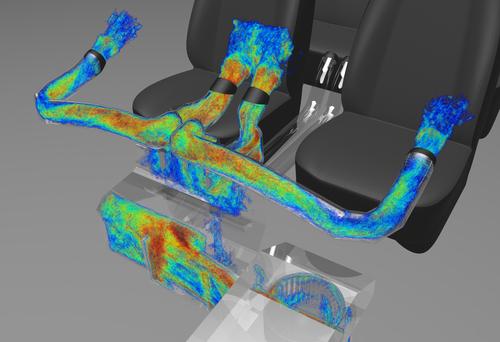

Over the years, simulation software has improved engineers' capability to visualize such systems, Perot explained, but more analytical capability was needed. This sparked the development of the "Find" module (for flow-induced noise detection) within its PowerAcoustics software to analyze airflows simulated with PowerFlow. Flow-induced noise sources, even those normally masked by turbulent airflow, are pinpointed in space by the Find model and their intensity quantified, enabling a precise localization and ranking of noise problems. Results can be visualized with underlying design geometry, easing discovery of findings and design improvements for engineers.

Perot said Exa's applications were able to produce robust data connected with their simulations, "but customers were complaining that it was too complicated. They asked for something easier." He said Find allows an engineer to locate, quantify, and rank noise sources and run before-and-after scenarios to evaluate the effects of design modifications. The data generated can be fed into Exa's simulation tools to allow 3D visualization of the results.

READ MORE ARTICLES BY AL BREDENBERG:

In a recent conference presentation, Jan Biermann, acoustic specialist at BMW, said the automotive industry has been successful at reducing interior noise caused by the engine, wind, and wheels, leaving HVAC as a priority area for improvement. The complexity and distribution of HVAC throughout a car, and the interaction with other systems, mean that design changes can be expensive and hard to implement. Thus, handling HVAC noise early in the development cycle is highly desirable.

BMW was previously applying computational analysis of its HVAC designs at the component or subsystem level. The piecemeal approach ignored the interaction among components and noises emitted by the system as a whole. Its engineers were unable to compute and compare the relative noise contributions of the various components to know which ones were the most important to target for improvement.

A joint study between BMW and Exa showed that PowerFlow simulation, along with PowerAcoustics and the Find tool, allowed engineers to carry out whole-system HVAC analyses for the BMW 7 Series and the Rolls-Royce Phantom. They were able to see how sound not only was generated but propagated through the system, from the initial source to the passenger's ear, according to Exa. Insights into the location and level of acoustic effects provided more accurate courses of action for noise reduction and meant that optimization decisions could be made early in the cars' development processes.

Al Bredenberg is a writer, analyst, consultant, and communicator. He writes about technology, design, innovation, management, and sustainable business, and specializes in investigating and explaining complex topics. He holds a master's degree in organization and management from Antioch University New England. He has served as an editor for print and online content and currently serves as senior analyst at the Institute for Innovation in Large Organizations.

Like reading Design News? Then have our content delivered to your inbox every day by registering with DesignNews.com and signing up for Design News Daily plus our other e-newsletters. Register here!

Design engineers and professionals, the West Coast's most important design, innovation, and manufacturing event, Pacific Design & Manufacturing, is taking place in Anaheim, Feb. 9-11, 2016. A Design News event, Pacific Design & Manufacturing is your chance to meet qualified suppliers, get hands-on access to the latest technologies, be informed from a world-class conference program, and expand your network. (You might even meet a Design News editor.) Learn more about Pacific Design & Manufacturing here.

About the Author(s)

You May Also Like