March 30, 2015

New industries and small companies are beginning to turn to the power of 3D simulation. Processing speeds are faster and big data processing is less expensive to deploy. Many companies that wouldn't ordinarily use simulation find it has become affordable from cloud-based service companies that sell processing by the drink. 3D simulation is also becoming easier to use, since you can now run your simulation while working on your CAD design -- even on a laptop.

Higher processing speeds can now be attained without resorting to a wall of servers. "Speed has helped people adopt simulation. In the past, when you ran simulation you had to have dedicated servers," Delphine Genouvrier, senior product portfolio manager at SolidWorkstold Design News. "New devices can run simulation on a laptop. The multicore of the machine is used and that means you can run it during the day and not have to wait weeks or months to get your results."

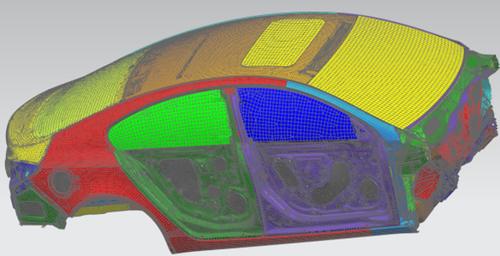

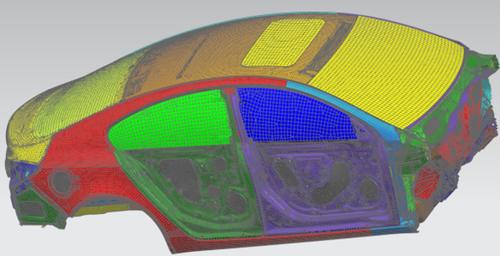

Simulation expands beyond automotive and aerospace

Ease of use and speed have attracted a wide range of new users to 3D simulation. For many years, simulation was used primarily in automotive and aerospace. It was used at the end of the cycle. "Now that it's easier to use and more people can use it, we're seeing the democratization of simulation," said Genouvrier. "Investment in simulation has been consistent in automotive and aerospace, but it's increasing in other industries. It's becoming mainstream."

MORE FROM DESIGN NEWS: Learning to Use Big Data

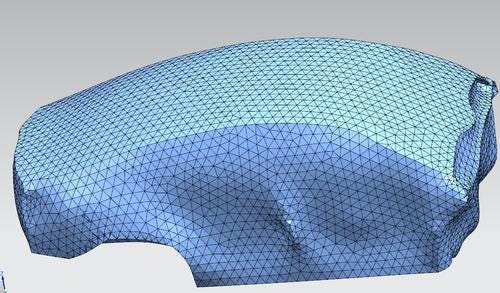

SolidWorks is finding that some of its new customers are coming from high tech and medical. "3D simulation is changing the world. High tech is now using simulation for the cooling process of their devices," said Genouvrier. She also noted that SolidWorks is getting customers from the life sciences. "In health and medical they're using simulation to track fluid inside a device," said Genouvrier. "When the velocity of the fluid is low in some areas, there is the possibility of bacteria growth because of dead zones. We can see that potential problem through simulation."

At Siemens PLM, product marketers are finding a similar diversification of customers for simulation. "We're seeing simulation used in electronics and energy, and to a lesser extent medical devices and consumer products," Ravi Shankar, director of simulation product marketing, told us. He noted that simulation can be used to look at how a bottle gets manufactured. If a company has adopted CAD, it's easier to create the shape, and see how the design is going to function. "This means companies that don't have dedicated analysts can still use simulation," said Shankar.

Small companies turn to simulation

Another shift in 3D simulation is the entry of smaller organizations. "In the past, it was only the largest organizations that used these tools. Now simulation is more affordable, so any product engineer using 3D CAD can also use simulation during product development," said Genouvrier. "Any product engineer can use simulation now."

MORE FROM DESIGN NEWS: The Power of CFD Simulation Early in Product Design

While 3D simulation is making its way into new industries and onto the laptops at smaller organizations, the tools are also finding their way into the engineering classroom. "In education, more and more students are using 3D simulation as part of their engineering school experience," said Genouvrier. "Students are exposed very early so when they go out to work, they're already familiar with simulation."

Rob Spiegel has covered automation and control for 15 years, 12 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years he was owner and publisher of the food magazine, Chile Pepper.

About the Author(s)

You May Also Like