July 16, 2014

A scientist at the University of Pittsburgh has achieved a breakthrough in the quest to create artificial cartilage with human cells for treatment of degenerative joint disease and other joint-related health issues.

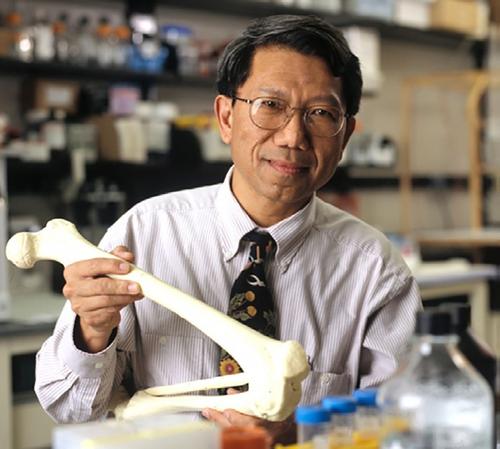

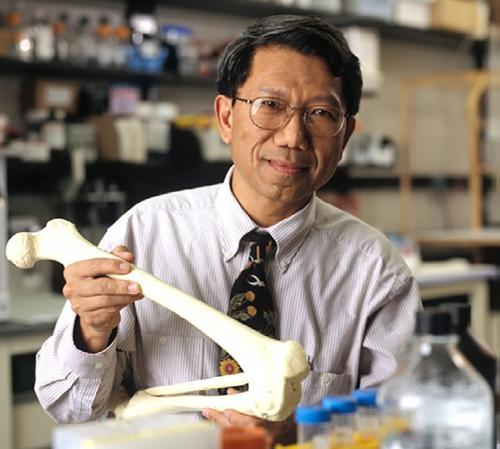

The work of Rocky Tuan, director of the Center for Cellular and Molecular Engineering and professor and executive vice chairman for orthopaedic research at the university's School of Medicine, has used a novel 3D printing method to create the first example of a model for living human cartilage grown on a laboratory chip.

The research is specifically aimed at people suffering from osteoarthritis, but it can be applied to people with debilitating joint problems such as soldiers who suffer injuries on the battlefield. It's a significant breakthrough in treating people who have degenerative joint breakdown by allowing doctors to understand how the disease develops far earlier than they normally would and then treat the disease with more targeted therapies, Tuan told Design News.

"The cartilage-bone junction, or osteochondral junction, is the part of the joint surface most affected by degenerative joint diseases, such as osteoarthritis, that represent the primary cause of physical disability," he says. "Understanding the initiation and propagation of this degenerative process is crucial to the development of disease-modifying osteoarthritis drugs."

It's been historically difficult to do this, however, because human patients normally don't know they have the degeneration until it's too late, so doctors can't get to the root of what started the disease early enough to treat it properly, Tuan told us. He notes that doctors also have attempted to observe the disease in animals, but because their weight-bearing system is different, it's hard to get a clear read on the problem.

"There is therefore a great need for an osteochondral 'tissue-on-a-chip' system that will permit the study of both how the disease begins and progresses, and to discover potential therapeutic agents," says Tuan.

To create artificial cartilage, three main elements are required -- stem cells, biological factors that make the cells grow into cartilage, and a scaffold that gives the tissue shape. Tuan has managed to achieve all three on a chip by molding into shape thin layers of stem cells that are embedded in a solution that retains its shape and provides growth factors. The key to Tuan's work is that it uses a novel method of 3D printing that uses visible light, which preserves human cell viability and health. Common 3D printing methods use 3D deposition, which is likely to damage cells, he told us.

"We used projection stereolithography, which uses sequential, layer-by-layer photo crosslinking to fabricate a 3D structure. By using photo-activatable natural polymers derived from native extracellular matrix, cells may be loaded in the solution, and are then encapsulated in the final hydrogel construct... [which] is viscoelastic, resembling native cartilage."

Tuan and his team will continue their work to build microtissue that can be applied to study any type of biological influences in joint health, including hormones, inflammation, and mechanical injuries.

Some of this work will include combining the 3D printing method with a novel nanofiber spinning method Tuan previously developed. This combination of methods could provide a stronger scaffold so researchers can create artificial cartilage that even more closely resembles human cartilage.

Related posts:

About the Author(s)

You May Also Like