November 12, 2013

Georgia Institute of Technology has done some truly bleeding-edge research in self-configuring robotics and robot swarms. It's also home to research projects in advanced additive manufacturing (AM), design, and materials. The latest one has received a grant from the Department of Energy to develop nanoscale AM with a variety of materials.

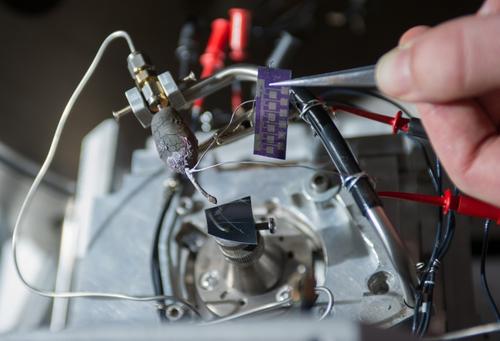

The technique uses focused electron beam induced deposition (FEBID) assisted by gas jets, which sends a highly focused beam of high-energy electrons and a jet of gases to a substrate material. The process creates tiny, nanoscale-layered structures, tens of nanometers to hundreds of nanometers wide, formed one atom at a time. The nanscale allow structures made of a wide variety of materials and materials combinations, and with very high purity.

Some different types of electron-beam AM systems are used for doing metals AM, often for aerospace applications. Examples we've told you about include Arcam doing work for aircraft engine maker Pratt & Whitney, and Sciaky making jet wing components for Lockheed.

The research team is led by professor Andrei Fedorov of Georgia Tech's school of mechanical engineering, whose specialties include heat transfer, combustion, and energy systems. The team envisions using the technique to make nano-electromechanical sensors and actuators, high-performance interconnect interfaces for electronic devices based on graphene and carbon nanotubes, and to design optical and magnetic materials with new properties by changing the shape and composition of their nanostructures and combining materials. "By providing truly nanoscale control of geometries, [the technique] will impact a broad range of applications in nanoelectronics and biosensing," said Fedorov in a press release.

Fedorov and his team have already demonstrated the technology, and a proof of principle for the use of thermally energized gas jets in the FEBID process. The researchers have also used the process on a variety of substrate materials, including metals, plastics, dielectrics, and semiconductors, with about two dozen deposition materials. They will use the $660,000 grant, which lasts for three years, to increase control over the process and speed up the growth of materials, while still maintaining a high aspect ratio of deposited material in the nanostructures.

"Wherever electrons strike the surface, you can grow the deposit," said Fedorov. "That provides a tool for growing complex three-dimensional structures from a variety of materials with resolution at the tens of nanometers. Electron beam induced deposition is much like inkjet printing, except that it uses electrons and precursor molecules in a vacuum chamber." Scaling up the process, in terms of increasing production volumes, will also be possible by adding electron beams and precursor jets working in parallel.

Related posts:

About the Author(s)

You May Also Like