December 4, 2015

If it looks like a 3D printer and acts like a 3D printer, then it should be a 3D printer, if one were to follow the old adage about ducks. But that doesn't hold true for a new invention by a robotics startup that looks like a 3D printer but, instead of printing CAD designs, it prints something very useful for electronics designer and other makers of electronic devices and equipment -- circuit boards.

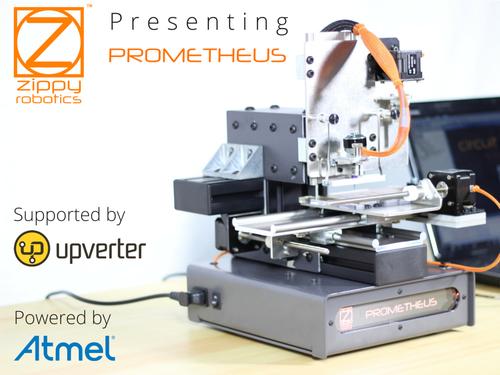

The machine, called Prometheus, is the brainchild of Rocco Tuccio, who together with his team at Zippy Robotics developed it. Prometheus can build real circuit boards in minutes at a fraction of the cost of professional-grade printed circuit board (PCB) milling machines, which was the impetus for developing it, he told Design News in an interview.

"We didn't like how expensive professional-grade PCB milling machines were," he said. "The nearest competitor that can meet or exceed Prometheus's level of detail costs upwards of $8,000. By slashing the price, the hope is that more people can get access to these tools." Prometheus is expected to retail around $2,599.

Tuccio said Prometheus will be a benefit to anyone who sees an advantage or convenience in being able to test their circuit designs very quickly. "Speed is the reason someone would want to use Prometheus or other PCB milling machines," he said. "It can drastically cut down development time because by making the board on your desk instead of ordering it through a manufacturer, you cut out all of that delivery time -- typically weeks for them to make it and ship it to you."

Prometheus also has similar benefits for prototyping that those using 3D printers to create prototypes see, Tuccio said. "The benefit really multiplies when you find that you need to modify your design -- you make another one again within the hour and cut out another waiting period," he said. "I see businesses benefiting, as well as individuals trying to get a product to market. Universities and maker spaces are a big focus of mine. There, each Prometheus machine can empower not one but many individuals."

Tuccio explained to us how Prometheus works. The machine starts with an off-the-shelf cooper-clad board, then uses its 45,000 RPM custom spindle to carve through the copper layer of the board. "By selectively removing areas of copper we can create the traces and component footprints we want and rapidly prototype our design," he said. "Prometheus can also drill holes and cut the board out into custom shapes."

READ MORE ARTICLES ON THE MAKER MOVEMENT:

Zippy Robotics also has partnered with Upverter to provide its users with professional design software, although any software that exports Gerber files can be used to create a circuit board with Prometheus, according to Tuccio. "But we prefer Upverter and they're giving Prometheus users a free account that includes extra private projects over their standard free account," he said.

Prometheus is getting some industry promotion in a blog post by semiconductor manufacturer Atmel, which provides technology for the machine. Tuccio and his team have also launched a Kickstarter campaign to raise funds to place a large enough order with the company's New Hampshire-based manufacturer, Rapid Manufacturing, to take advantage of volume discounts so Zippy can deliver the machine at a lower price, he told us. It also is offering the machine for an early bird price of $1,899 on Kickstarter.

In the meantime, with the design of Prometheus already complete save minor updates, Tuccio and his team are busy testing the product to acquire the required certifications for the US, Canada, and the European Union so they can begin selling the product in November 2016. The company plans to sell direct to consumers via its website and also is in talks with distributors of electronic components and equipment to sell Prometheus that way.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 15 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

Like reading Design News? Then have our content delivered to your inbox every day by registering with DesignNews.com and signing up for Design News Daily plus our other e-newsletters. Register here!

Design engineers and professionals, the West Coast's most important design, innovation, and manufacturing event, Pacific Design & Manufacturing, is taking place in Anaheim, Feb. 9-11, 2016. A Design News event, Pacific Design & Manufacturing is your chance to meet qualified suppliers, get hands-on access to the latest technologies, be informed from a world-class conference program, and expand your network. (You might even meet a Design News editor.) Learn more about Pacific Design & Manufacturing here.

About the Author(s)

You May Also Like