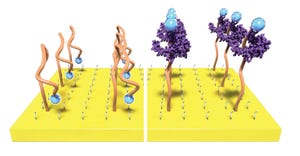

Sensors

super fast 3D printing

Industry

Intelligent Industrial Camera Eyes Supplier NewsIntelligent Industrial Camera Eyes Supplier News

We’re also looking at sustainable industrial automation, variable frequency drives, and fluid control technologies.

Sign up for the Design News Daily newsletter.

.gif?width=300&auto=webp&quality=80&disable=upscale)

.jpg_(1).png?width=300&auto=webp&quality=80&disable=upscale)

.jpg?width=300&auto=webp&quality=80&disable=upscale)