Researchers at the University of Colorado Boulder have figured out how to do what many thought was impossible: recycle carbon fiber composites into new material with virgin strength characteristics, cheaply and quickly.

March 22, 2016

Colorado researchers have been busy in the area of recyclable materials. As we told you in January, a Colorado State University team developed a polymer synthesis process that makes polymers recyclable back to their original molecular state using heat. The result is a new class of sustainable biopolymers that are both biorenewable and recyclable.

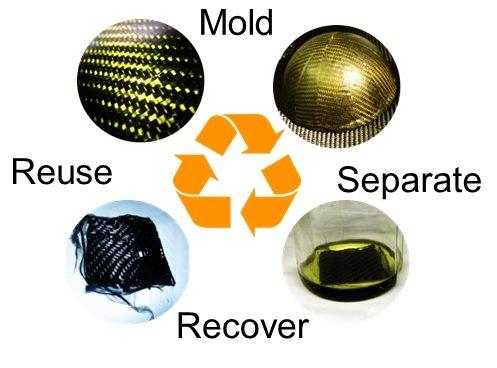

Now, researchers at the University of Colorado Boulder have figured out how to do what many thought was impossible: recycle carbon fiber composites into new material with virgin strength characteristics. That goes for both the carbon fiber and the glue: both can be completely recycled simply by soaking the composite in an organic solution at room temperature. The fabrication process and the process of recycling the material are comparatively fast and energy efficient.

Researchers at the University of Colorado Boulder have figured out how to do what many thought was impossible: recycle carbon fiber composites into new material with virgin strength characteristics, cheaply and quickly.

(Source: University of Colorado Boulder)

Recycling, as well as repairing, composites has been a bugaboo of the technology for a long time. Especially for carbon fiber composites, both recycling what's already been produced, and making materials that are easier to recycle in the first place, are tough to do, sending millions of pounds to the landfill. Attempting to repair damaged carbon composite parts, such as a smashed car hood, makes this clear. Although the glue can be broken down, processes are often expensive and energy-intensive, and can result in toxic waste. The composites can be crushed, but the resulting short fibers aren't nearly as strong as long fibers.

READ MORE ARTICLES ON COMPOSITES:

To date, most attempts at carbon composite recycling typically use high-temperature pyrolysis for the resin, plus melting or chopping the fibers, but both of these processes can reduce quality. More of the resin can be retained and higher quality fiber can be recovered when chemical processes at lower temperatures are used on materials designed to be recycled, such as Chinese-headquartered Adesso's. A different process that promises higher quality is Adherent's carbon fiber recycling using wet-chemical breakdown of the composite's polymer matrix. It results in a short fiber that retains 95% of the virgin fiber's strength.

The University of Colorado team wrote up their research in an article in Advanced Materials. The lead author, Philip Taynton, is so certain their method will prove commercially viable that he's co-founded a startup company to bring the novel carbon fiber composite to market. Speed has a lot to do with that: the new composite can be fabricated much faster than others, which often require an hour to cure. The University of Colorado team's composites can be formed in only 60 seconds, which is blazingly fast in the world of, for instance, high-volume automotive manufacturing.

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 28 years, covering manufacturing materials & processes, alternative energy, machine vision, and all kinds of communications.

About the Author(s)

You May Also Like