Thermal cameras provide obvious nighttime crash-avoidance benefits but have been held back by cost.

“Thermal now reminds me of lidar five years ago,” remarked Wade Appelman, chief marketing officer for Owl Autonomous Imaging in an interview at CES in Las Vegas.

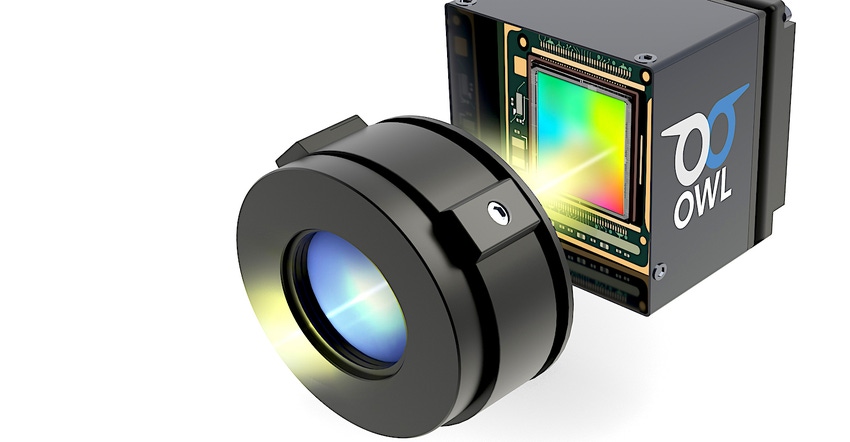

The company specializes in infrared thermal cameras for driver assistance and the computer vision software that maximizes the benefit of such cameras. The obstacle to adopting infrared cameras is similar to that faced by lidar: “The challenge in thermal is to get the cost down,” he said.

At CES, Owl debuted what it dubs the Thermal Ranger Platform, a thermal camera system combining the camera, an NVIDIA Jetson AGX Orin AI processor, and the Owl software suite. This includes Convolutional Neural Networks (CNNs), ROS applications, AI/ML framework and drivers, and necessary cables and adapters. The CNNs operate on the thermal images to provide 3D Object classification and ranging information using the Robot Operating System (ROS) Publish/Subscribe interface. Several example ROS applications are also included.

In addition to the software required for operation of the NVIDIA processor, the following modules are included:

Owl AI/ML Neural Networks

Autonomous Emergency Braking application

3D Birds-eye-view application

Object segmentation

Raw thermal video viewer

Raw thermal video recorder

Thermal with both 2D and 3D bounding boxes and colorized range data

There is good reason to consider infrared cameras, as vehicles increasingly turn to sensors to address issues such as the fact that three-quarters of pedestrian fatalities occur after dark, according to OWL.

Today’s optical camera-based collision-avoidance systems are failing in these after-dark situations, according to the Insurance Institute for Highway Safety. In recent tests, IIHS found that more than half of the collision-avoidance systems evaluated could identify pedestrians in the dark.

In the company’s white paper, “Infrared for ADAS and Robotic Mobility Applications,” Owl also points out that infrared works better than visible-light cameras in other conditions that can obscure the view ahead:

“Outdoor imaging applications often include situations where viewing conditions are less than ideal. In these situations, referred to as DVEs (degraded visual environments) the viewing path may be obscured by water in the form of rain and fog or smoke from a variety of sources. The performance of imaging systems in the presence of obscurants varies substantially.

Both MWIR (mid-wave infrared) and LWIR (long-wave infrared) can see through fog and smoke better than shorter wavelengths because the particles in these obscurants are smaller than the LWIR wavelengths. Smaller relative particles scatter less so the scene rather than the obscurant provides most of the signal.”

The benefits seem obvious, but the cost difference between a visible light camera and an infrared camera are orders of magnitude. This is because a device needed for the IR cameras is very expensive. That part is the microbolometer, which is an array of image detector elements that are each constructed from an absorber supported by a mechanical suspension platform on legs that conduct electricity.

The microbolometer is encapsulated in a vacuum that provides insulation. The tiny legs’ proportion equates to the sensor’s frame rate and the sensor is controlled by a readout integrated circuit mounted beneath the array of sensor elements.

Owl uses its own IR image sensors for its thermal cameras, which the company says will help it trim costs. “We think we’ll get the cost of these sensors into the hundreds of dollars versus thousands of dollars now,” said Appelman.

Additionally, the march of progress will also contribute, as Owl will move from older 8-inch silicon wafer technology to new 12-inch wafers, which will mean more chips per wafer and lower cost per chip.

About the Author(s)

You May Also Like