Siemens is making its NX design software smarter. Literally.

Siemens Digital Industries Software has added artificial intelligence to its popular NX software suite, which is part of the company’s Xcelerator line of software and services. That AI, along with advanced simulation tools, promises to speed customers’ innovation.

In the case of Red Bull Racing, the need for speed is literal. Though in the case of the team’s use of NX, it refers to shortening the time from initial design to wind tunnel testing to just ten days, and not the velocity of the team’s race cars. Though, ideally, those cars will also be faster as a result of the design and testing. “With NX and Teamcenter, we can effectively manage logistical challenges, increased design complexity, the growing number of parts, and thousands of engineering changes per year,” noted Red Bull Racing CIO Matt Cadieux.

These upgrades are the highest-profile responses to 1,200 customer requests for improvements that were addressed in the latest release of NX, according to Siemens. “In the latest revision of NX, Siemens Digital Industries Software has smoothly woven topology optimization design from requirements, through to component generation, additive manufacturing, and final machining by leveraging their convergent modeling and automated model-based definition authoring for PMI generation together with task-based collaboration," said Dr. Ken Versprille, Executive Consultant for market research firm CIMdata. “Users will welcome the effortless user interface that guides stakeholders through each step of the process.”

Take a look at some of the important upgrades:

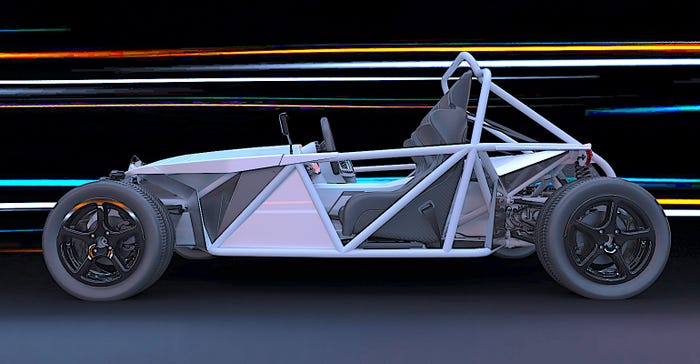

NX Topology Optimizer helps to create parts based purely on functional and design space requirements, resulting in fully editable convergent bodies that would be almost impossible to design and engineer manually. Inevitable design changes can be quickly made, optimizations and any downstream features updated automatically – saving time, effort and maximizing reuse of intelligence design and engineering data.

Design Space Explorer combines design space exploration with generative engineering to help designers automatically optimize a design against multiple objectives. Design engineers define the optimization problem with all parameters, constraints, and objectives in place and NX uses Simcenter HEEDS software to conduct multi-objective parameter optimization.

Increased Artificial intelligence and Machine Learning in the Selection Prediction and Select Similar commands uses shape recognition to quickly identify geometrically similar components, while the NX Voice Command Assist allows the user to invoke commands, navigate multi-level menus and operations as well as teach the system words or phrases to carry out common tasks.

Lattice Structure Optimization within NX using Siemens’ Simcenter 3D simulation to derive the optimal lattice structure in a singular environment - eliminating the multiple design analysis steps required traditionally.

Part Orientation Optimization brings nesting of parts (and their associated supports) within a machine build area along with integrated cloud-based orientation optimization processes to find the optimal build orientation for reduced thermal distortion. Siemens continues to deliver advanced capabilities in additive manufacturing that are designed to help our customers optimize their overall design and manufacturing processes.

“With each new release of NX, Siemens is pushing the barriers of what product development systems are capable of,” said. “Our shift to continuous releases of NX is proving incredibly popular with our community – enabling us to deliver industry-leading capabilities more quickly than before,” observed Bob Haubrock, Senior Vice President Product Engineering Software for Siemens Digital Industries Software. “This means providing access to new tools and technologies so they can be applied to our customers’ design, engineering and manufacturing challenges to help them overcome them more quickly.”

About the Author(s)

You May Also Like