The company predicts that 30 percent of commercial vehicles will be fuel cell or battery electric by 2035.

There are few components more closely identified with internal combustion than the piston and few companies more closely identified with pistons than Mahle. With an eye on an electrified future, the German supplier has announced a range of products to reinforce its position as an EV supplier.

Recognizing the industry’s direction, Mahle is aggressively plotting a new direction. “We are therefore concentrating our development activities on three areas: battery electric drives and fuel cells, thermal management, and highly efficient, clean combustion engines,” said Michael Frick, Chairman of the MAHLE Management Board (ad interim) and CFO.

Mahle has identified an opportunity to supply electric motors for commercial vehicles, which place a premium on the ability to provide continuous high power. About 20 percent of Mahle’s business is in the commercial vehicle segment, so it is important that the company is competitive in that market.

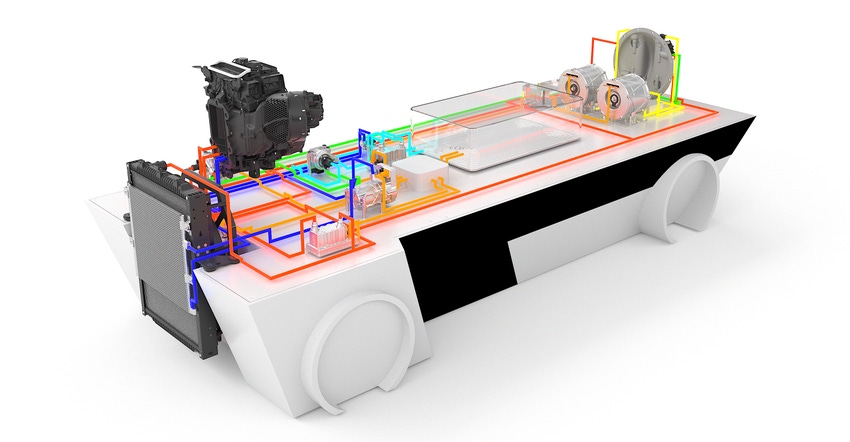

Typically, electric motors provide their peak power for a short time and then drop to around 60 to 70 percent due to heat build-up. An innovative integrated oil cooling system lets Mahle’s new Superior Continuous Torque (SCT) motor operate continuously at more than 90 percent of its peak power, making it ideal for hard-working commercial vehicles.

“It can run indefinitely at high power and is significantly smaller and lighter than a conventional electric motor with the same continuous power,” stated Mahle’s announcement. “This makes it suitable for use in all vehicle classes, including heavy commercial vehicles.”

Heavy commercial electric vehicles will quickly drain battery packs, making them ideal candidates to use hydrogen fuel cells as their source of electric power. Mahle aims to make components for these fuel cells, much as it made internal components for combustion engines rather than complete engines.

Fuel cells need for the air flowing through them to be moist, so Mahle has developed a flat membrane humidifier for this application in a program sponsored by Germany’s Federal Ministry for the Economy and Climate Protection (BMWK). Humid air boosts the fuel cell’s efficiency, and by keeping it from drying out, prolongs its life.

Mahle also introduced a new DC/DC converter that lets fuel cells provide power to electric drivetrains. It is more than 97 percent efficient and handles output as high as 180 kilowatts.

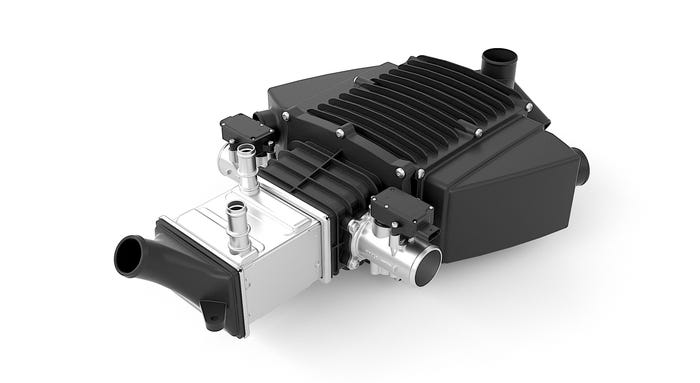

As hydrogen fuel becomes more widely available, there is the possibility of using it in combustion vehicles, making them cleaner than when they burn petroleum fuel. Mahle has developed a slate of products, including its signature pistons, that are optimized for use in engines that burn hydrogen.

The complete system includes pistons, piston rings, connecting rods, pins and, if necessary, a cylinder liner as well as a high-pressure impactor for flushing the crankcase. This move makes sense, because if 30 percent of the commercial vehicle market is electric in 2035, then 70 percent will still need piston engine components, even if some of them may shift to alternative fuel sources.

About the Author(s)

You May Also Like