Long range combined with high resolution and all-weather functionality will boost lidar ADAS utility.

Lidar’s utility as a mobility sensor is limited by some technical challenges; existing technologies can deliver long range, high resolution, or a fast scanning rate, but not all three at once, in all weather.

These technical shortcomings don’t even consider practical matters like the durability of the moving parts employed by lidar systems, or the high cost of those sensors.

Israeli startup Opsys Technologies promises to upend this paradigm with the delivery of long range, high resolution, and all-weather reliability in a solid-state device with no moving parts. While exciting new technology proposals hold promise for the future, they don’t mean much until the parts are actually in use.

That’s why the announcement that Opsys signed with South Korean supplier SL Corp is significant. The partners plan to deliver these eagle-eyed ADAS sensors for use in production cars starting in 2024 or 2025, according to Opsys chairman Eitan Gertel.

The company was originally focused on the optics industry. Hence its name. But they recognized the opportunities available in the lidar industry, and pivoted to that in 2016, Gertel explained. They worked to accumulate intellectual property for a few years and built prototypes before finally meeting with prospective customers in mid-2019.

Then the world went on “pause” for a while, which help up progress, but Opsys has been able to deliver A-zero engineering samples to prospective customers and plans to advance to B-zero samples during early 2022. This will give suppliers like SL Corp. hardware that is ready for automotive qualifications, but software that is still a work in progress, said Gertel.

“We will have the full module with the right software to finish automotive qualifications by end of 2022,” he promised. SL Corp. makes automotive headlight and taillight assemblies, and the small size of the Opsys lidar will permit that company to embed the sensors into those light assemblies so that automotive OEMs need not make any changes to accept the lidar. “They like the performance, but they also like the small size,” Gertel observed. “It is like a drop-in package for them.”

But that is just the beginning because Opsys has lined up additional suppliers with ambitious goals. “We have two more contracts to announce with Chinese Tier 1 suppliers,” he said. “They are talking about the million cars per year level in the 2025 time frame.”

Opsys lidar is appealing because it delivers the cost and durability advantages of solid-state flash lidar with the better range and resolution of mechanical-sweep or oscillating mirrors (MEMS and galvanometer systems).

The problem with flash lidar is that these devices are required to limit their instantaneous power so that the laser doesn’t present a hazard to the vision of oncoming drivers. This limits its range to only about 50 meters, said Gertel.

MEMS and rotating lidars have longer range, but they have moving parts to wear or are sensitive to low temperatures, he added.

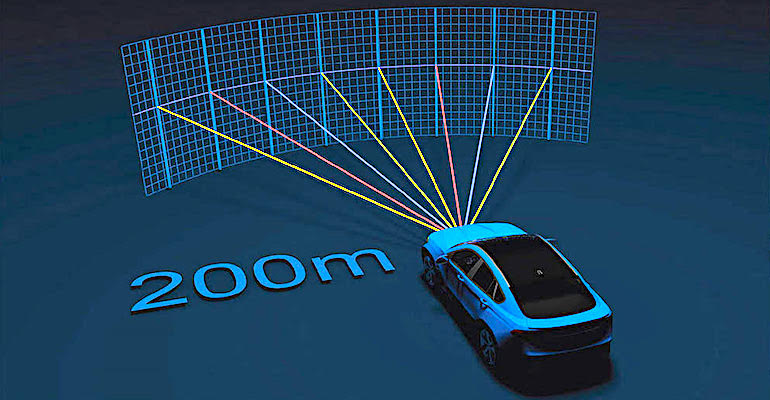

Employing Opsys lidars that are tuned for their specific application produces differences in performance. For example, forward-looking sensors value high resolution and long range, so these can be tuned with a narrower field of view to provide 0.1-degree resolution, explained Gertel.

“If you go from 0.1-degree resolution to 0.2-degree resolution you double the field of view.” This is how Opsys provides a wider field of view for its side-facing devices. “For the side, you don’t need 300 meters at high resolution,” he said.

“How do you cover the full field of view? You use a compound sensor: Take a few of those blocks and connect them together.” Come 2025, we'll be able to have a look for ourselves at what kinds of picture they combined lidars paint for ADAS systems in new cars.

About the Author(s)

You May Also Like