Widely spaced cameras provide accurate object detection and distance information like lidar at a lower price.

Somerville, Mass. camera vision startup Nodar has released a software developers kit for its Hammerhead stereoscopic vision system, with the goal of letting new partners rapidly assess and integrate the company’s 3D vision.

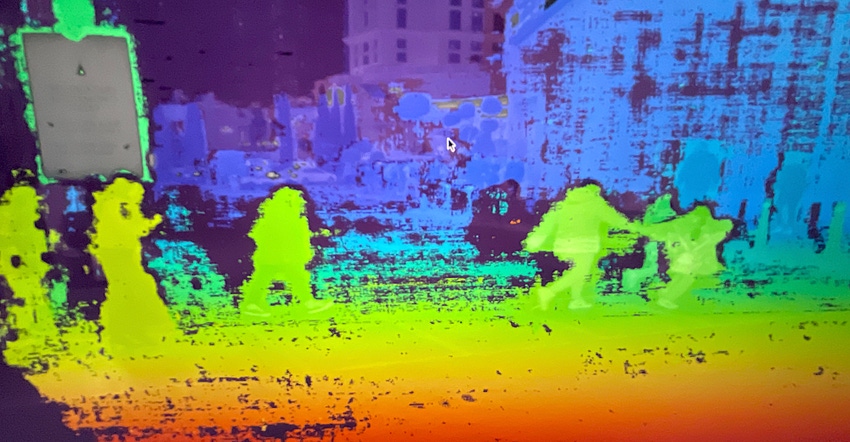

The kit includes hardware, software, and tools that autonomous vehicle developers need to employ Nodar’s Hammerhead technology, which uses a widely spaced pair of cameras to produce high-fidelity 3D point clouds in real time, similar to those created by lidar sensors.

Nodar chose the Hammerhead name in tribute to the distinctive-looking sharks that boast the most widely spaced eyes in the animal kingdom. The approximately two-meter spacing possible on passenger cars (and three meters on commercial trucks) is the key to the system’s ability to triangulate distance to objects spotted by the cameras, which can be mounted on outside mirrors or incorporated into headlight housings.

The company has recently scored a $1.7 million U.S. Army contract for testing Hammerhead’s effectiveness in harsh weather. Design News had the opportunity to speak with Nodar CEO Leaf Jiang to discuss Nodar’s Hammerhead technology.

Design News: What is Nodar’s proposition?

Leaf Jiang: High quality, dense, 3D point clouds at camera prices with smart software and no calibration engineer required.

DN: How does Nodar technology work?

Leaf Jiang: Nodar technology is essentially a wide-baseline stereo vision sensor. We are a software company that enables the ability to take the full width of a vehicle and we solve the alignment problem that’s endemic in stereo vision. The requirement of these cameras is typically that they have to be stabilized within one-hundredth of a degree and we just do all of that through software, with no need to ship a calibration engineer with the product.

We use the rectified images to generate high-quality 3D information and we have intellectual property around that to generate point clouds that almost look like they come from lidar systems.

DN: How does Nodar’s solution compare to lidar?

Leaf Jiang: They are similar in that they both measure physical quantities. This is why people love them for automotive; they need a reliable measurement for safety-critical systems. Lidar measures time of flight, the time it takes a photon to go out and come back. So it is a mapping between time and distance.

Our system is triangulation-based. We measure angles to determine distance. So its not an interpreted measurement. It differs in a couple fundamental ways. We believe that our system has longer range and higher resolution than lidar can offer.

The longer range comes because of the physical property of lidar. There’s only so much power that you can transmit safely for eye safety. So there’s a physical limit to the distance. Second, the resolution, or area coverage. Light is limited by the speed of light. In order to see a complete scene of five million pixels that are 150 meters away you actually have to wait for the light for about five seconds for that scene, and that’s not fast enough.

If you’re trying to see small objects in the road at long distances, it is much faster and easier to do with a camera-based system.

DN: What are Hammerhead’s detection capabilities?

Leaf Jiang: The capability that we’ve added to do high-quality calibration of stereo sensors involves three things. One, being able to calibrate off of natural scenes, not checkerboards or calibration targets, without user intervention over 15 years. Second, being able to do that calibration fast enough frame by frame to deal with the vibration of the vehicle. And third, being able to do it accurately enough so that we can estimate things at 1,000 meters.

DN: Who are your target customers?

Leaf Jiang: Anyone who needs high-quality 3D information. Right now we’re focused on automotive OEMs and Tier 1 suppliers. But it is a technology that is pretty general and useful to other robotics companies as well as construction, agriculture, and military.

About the Author(s)

You May Also Like