Ford will revamp its Oakville, Ontario plant into a new EV and battery manufacturing complex.

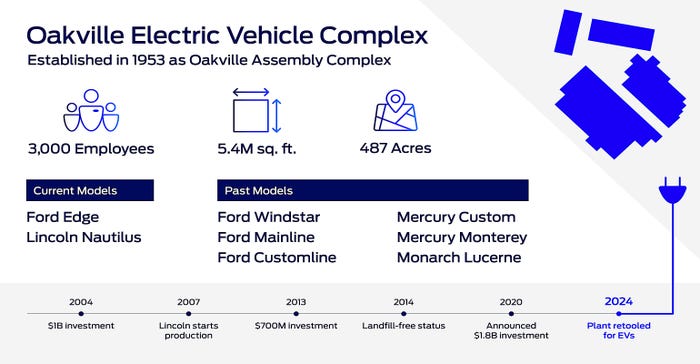

Ford is bringing its Canadian manufacturing assets into its EV fold, with the announcement of a $1.8 billion conversion of the company’s Oakville (Ontario) Assembly Complex to the future Oakville Electric Vehicle Complex.

The conversion is scheduled to commence in the second quarter of 2024 and the factory will roll out its first EV in 2025. Currently, the 5.4-million-square-foot plant employs 3,000 workers who build the Ford Edge and Lincoln Nautilus crossover SUVs. Ford has spent $1.7 billion on the facility since 2004 to keep it up to date and achieved landfill-free status for Oakville manufacturing in 2014.

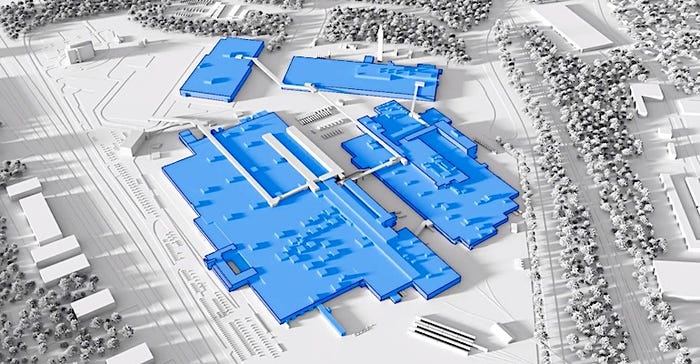

This complex will incorporate both battery assembly and vehicle assembly. The 487-acre site currently includes three body shops, one paint building, and one assembly building. When converted for EV production, the campus will feature a new 407,000 square-foot on-site battery plant that will assemble battery cells and arrays made at Ford’s future BlueOval SK Battery Park in Kentucky. The resulting heavy battery packs will go straight into vehicles that are also built on-site at Oakville.

“Ford of Canada has been a leader in the country’s auto industry since it was founded 119 years ago, driven by hard-working, dedicated employees,” said Bev Goodman, president and CEO of Ford of Canada. “As the top-selling auto brand in Canada for 14 straight years, the successful transition to EV production in Oakville will help deliver stable Canadian employment with the opportunity to build the new skills and expertise to drive Ford and the industry forward.”

While shiny new greenfield facilities such as Ford’s BlueOval City in Kentucky draw plenty of attention, the company is also refurbishing existing facilities for us in the EV age. The Cologne, Germany plant will commence production of a new European-market battery-electric Ford Explorer later this year.

In addition to Ford’s many American facilities gearing up for battery and EV production, the company is similarly adding battery capacity in Europe to support the Cologne plant’s EV assembly. The company signed a memorandum of understanding with LG Energy Solutions and Koç Holding to build one of Europe’s largest commercial electric vehicle battery cell production facilities near Ankara, Turkey, later this year, with production to start in 2026.

About the Author(s)

You May Also Like