Fabric structure and high fiber content of continuous-fiber-reinforced thermoplastic prevent flames from spreading; flame-retardant product variants with UL 94 V-0 classification; suitable for use in flame-resistant high-voltage battery components and inductive charging.

March 31, 2020

Tepex continuous-fiber-reinforced thermoplastic composite materials from Bond-Laminates demonstrate excellent fire resistance even without flame-retardant additives due to the special structure of the semi-finished products. This is the result of comprehensive investigations and tests that the Lanxess subsidiary – partly in cooperation with external testing institutes – has carried out with a view to typical Tepex applications and installation situations. “The tests also showed that our composites are highly suitable for structural components and housing components in high-voltage batteries for electric vehicles, which, for safety reasons, need to have excellent flame-retardant properties,” says Dr. Stefan Seidel, head of Research and Development at Bond-Laminates. “The materials here present a lightweight alternative to aluminum. They enable cost-effective component solutions thanks to the cost-reducing integration of functions and simple processing in the hybrid molding method without the need for rework.”

|

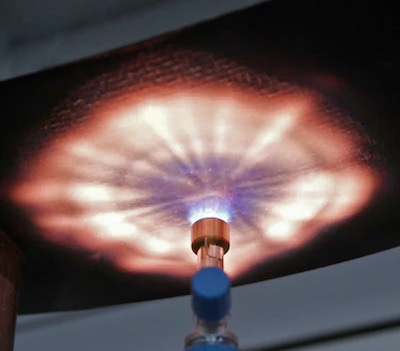

LXS-IMG_Tepex_Flammschutzprfung Sitecore Internet Image 400x351.jpg The reason for the good flame-retardant properties of Tepex is the high content of flame-resistant continuous fibers and the comparatively low proportion of flammable plastic. Photo: Lanxess AG |

The flammability tests performed included US test FMVSS 302 (Federal Motor Vehicle Safety Standard) for the burning characteristics of materials for car interiors. This investigates the rate of combustion. Tepex variants that are not flame-retardant already perform well in the test. They do ignite, but the flames hardly spread within the allotted test time.

Non-flame-retardant Tepex variants were also tested in the fire pan test in accordance with UN regulation 180, 6.2.4. The test specimen lies flat over a tub of burning fuel and is exposed to the fire directly for 70 seconds and less directly for 60 seconds. This test is a particularly realistic reflection of the fire situations Tepex might face in typical applications such as underbody paneling components. As Seidel says, “There are no holes in the composites, nor do the fibers burn in either test. The plastic does not exhibit any dripping-burning either, and the test specimen goes out by itself.” The reason for these flame-retardant properties is the high content of flame-resistant continuous fibers and the comparatively low proportion of flammable plastic.

The investigations also showed that the UL 94 test does not provide any reliable results for the actual fire behavior of Tepex. The reason is that the vertically fastened test specimen is exposed to a flame from the edge. “This approach does not match typical Tepex installation situations. Our composite material is normally used overmolded and back-injected, which impedes the flame’s access to the fiber ends,” says Seidel. For applications in which V-0 classification is compulsory, Bond-Laminates offers halogen-free, flame-retardant Tepex based on polyamide, polycarbonate and polyphenylene sulfide. For example, the polycarbonate product type is listed on the UL Yellow Card as V-0 for test specimen thicknesses of between 0.4 millimeters and 2.2 millimeters.

Due to the major potential applications of Tepex in powertrains of electric vehicles, Bond-Laminates has used its own test setup to comprehensively investigate the fire behavior of overmolded, polyamide-6-based Tepex. A “HiAnt carrier” was used. This is a U-shaped profile made of Tepex, the inside of which is reinforced with crosswise ribs made of various polyamide 6 types such as Durethan, with or without a flame-retardant package. This practical test specimen is exposed to a 900°C flame in six positions for between 30 seconds and five minutes – for instance, on the polyamide ribs or on areas that have not been overmolded.

Non-flame-retardant Tepex again confirmed its inherently excellent fire resistance in this test. This is because only the molded rib material is burning after five minutes of flame treatment – and only when it is not equipped with special flame retardants. By contrast, if the ribs and overmolded areas made from a flame-retardant polyamide pass the test, the flames do not spread from the site of the fire treatment, but rather die when the burner is removed. “So, using non-flame-retardant Tepex with a flame-retardant injection molding material offers a very substantial safety margin for the design of flame-retardant components. We see enormous potential for this material combination to be applied in high-voltage battery components such as housings and partitions, but also in floor plates for inductive battery charging systems,” says Seidel.

About the Author(s)

You May Also Like