Reinforced structural insert for A-pillar with Tepex; infant carrier with ultralight, composite-based headrest; trend towards sustainable composites in the sports, automotive and IT industries.

February 28, 2020

New trends in transportation are opening up a wide range of potential applications for semi-finished products made with the Tepex continuous-fiber-reinforced thermoplastic composite from Lanxess, which has long since become established in large-scale production. “The focus of our activities at JEC World will therefore be on a wide range of applications of our composites in the lightweight construction of electric vehicles, in seat designs for autonomous driving and in safety-critical components such as child seats and infant carriers,” explains Henrik Plaggenborg, head of the Tepex Automotive Group at Lanxess. JEC World will now take place in Paris in May, having been postponed from its original dates of March 3 to 5 due the coronavirus outbreak.

|

Seat backs are promising applications for continuous-fiber-reinforced thermoplastic composite. Image courtesy of Lanxess. |

Tepex is developed and produced by Lanxess subsidiary Bond-Laminates GmbH in Brilon, Germany. Additional thematic focal points at the Bond-Laminates JEC World stand will include new material and technological developments for consumer electronics and the IT industry as well as sustainable composites for the sporting goods industry and laptop manufacturers, for example. Tepex applications that require outstanding flame-retardant properties will also feature.

Lightweight design is gaining in importance due to increasingly strict exhaust regulations and the move towards electric vehicles. Tepex also opens up enormous potential for weight savings in the vehicle body. Lanxess will be demonstrating this at JEC World, using the example of an A-pillar with a 3D hybrid design that Porsche has developed for vehicles such as convertibles and roadsters and is used for the first time in the Porsche 911 Cabriolet. It comprises an insert made from high-strength steel, a supportive and formed section of Tepex, a ribbed structure made from a polyamide 66 Durethan, and a structural foam. “Thanks to the hybrid insert, the A-pillar is just as stable in the event of rollovers as previous designs featuring a high-strength steel tube, but it is around five kilograms lighter,” says Plaggenborg.

A child seat headrest developed as a technology demonstrator by Lanxess partners as part of a project funded by the German Federal Ministry for Economic Affairs and Energy will also be on show. It is produced in a particle-foam composite injection molding (PCIM) process and contains an insert made from Tepex. “In comparison with the commercially produced component variant, the weight of the headrest is up to 30 percent lower without compromising its excellent crash performance. The production process is also simplified because the number of parts is reduced from six to one,” explains Plaggenborg.

Bond-Laminates is continuously expanding its portfolio of materials to include sustainable fiber-reinforced composites. The focus here is on both the thermoplastic matrix and the reinforcing continuous fibers. The latest commercially available development is a Tepex variant based on recycled polycarbonate materials made from post-consumer waste. It meets all known requirements that were placed on the previous material formulation. “We are also working on using bio-based fiber and matrix systems and recycled carbon fibers,” explains Dirk Bonefeld, head of Marketing & Sales Consumer Electronics, Sports and Industry at Bond-Laminates.

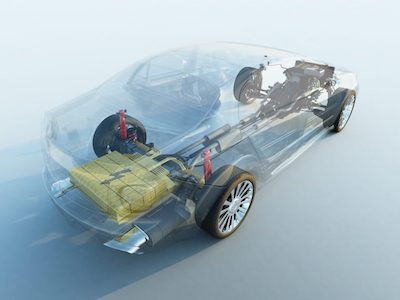

Another topic at the Bond-Laminates JEC World stand concerns Tepex applications in components for electric vehicles that require outstanding flame-retardant properties – such as carriers for electrical and electronics modules and battery cover plates. “As a result of its structure, Tepex has very good flame-retardant properties even without flame-retardant additives and it passes numerous flammability tests with good results,” explains Bonefeld. Nevertheless, the range also contains flame-retardant product variants based on polyamide and polycarbonate that fulfil the requirements, for example, of the flammability test as per US standard UL 94 with the top classification of V-0, even at low wall thicknesses.

Lanxess has recently increased production capacity for Tepex in Brilon by around 50 percent. “In doing so, we are responding to the huge demand for our composite materials in the mass production of highly stressable components for lightweight vehicles and consumer electronics in particular,” says Bonefeld.

About the Author(s)

You May Also Like