Costly specialized inspection robots might be the latest product disrupted by smartphones.

Quality assurance inspections of auto parts are such a tedious task that they can really only be performed reliably by AI, according to Daniel Davenport, Senior Director of Automotive at Capgemini. Watching parts stream past from an assembly line is a sure way to bore a human inspector into missing flawed parts when they appear, he said.

“Seals, welds, sockets, lug nuts; these are things that are incredibly difficult for a human to inspect reliably,” Davenport said. “A 10-hour shift shows the advantage of computer vision.”

The trouble is that specialist computer vision inspection systems have been expensive. And setting up such systems has been slow, according to Davenport, requiring as long as four months to install cameras to gather information on defects in products.

Worse, the desktop-based analysis platform kept its information captive, causing delays and re-work because of a lack of company-wide visibility of the quality data.

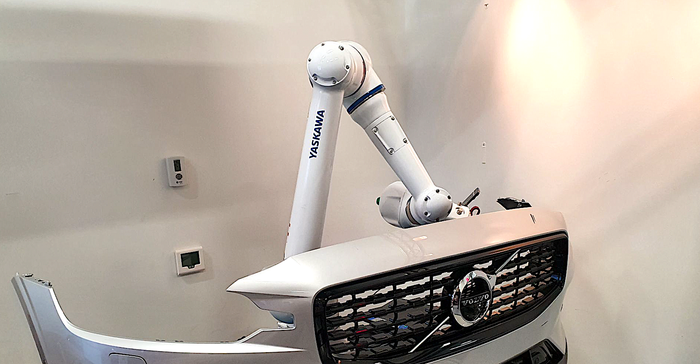

Working with industry expert John Ward at the University of South Carolina, Capgemini has developed a simpler visual inspection system that distributes its analysis using Verizon 5G. There are few of the dedicated vision systems for manufacturing that support 5G, but Ward’s team at USC found an off-the-shelf solution: an Apple iPhone 13 running IBM’s Maximo visual inspection application.

The system aims to exploit 5G’s high speed and low latency to:

Deliver high-resolution images in real-time

Expedite the inspection process

Improve productivity

Remediate potential problems before they occur

Capgemini’s role is to provide advanced analytics that let manufacturers enjoy a centralized view of defects spotted by Maximo. “We have joined to support some of the demos by getting the data off a standalone product, into the cloud, and into a dashboard reporting system,” explained Davenport.

Putting an iPhone into the grip of an industrial robot arm to inspect parts instead of building a conventional machine vision system yields a cost savings of 10-15 times, he said. This is just for the inspection system, but the real cost benefits come downstream, from the reduction in the re-work and warranty costs, Davenport added. “OEMs can tell us what their rework percentages or warranty expenses are, so they can see a real-time return on investment.”

The system can also provide visibility to increases in defects that occur at specific times, which could point to the need for additional training for particular workers, he pointed out.

The team has already proven the system at an unnamed OEM’s manufacturing facility, according to Davenport. It is easy to convince companies to give it a try because of the low cost of a single inspection station and the ease with which the solution can be scaled to increased use.

South Carolina is home to assembly plants for Volvo and BMW, along with tire-maker Michelin, so there are many opportunities for the University of South Carolina to work with nearby factories to boost quality and save money for hometown manufacturers.

About the Author(s)

You May Also Like