Yet even with the good sustainability marks for manufacturing, supply chains were showing vulnerability long before that pandemic hit.

August 17, 2020

Looks like manufacturers are doing quite well in cleaning up their processes. In the world of enterprise sustainability, manufacturers led the way over food and beverage, construction, and wholesale transport.

EcoVadis collected fresh data from more than 40,000 companies across five geographic regions from 2015 to 2019. The report on the data compares manufacturing to other industries and breaks down the different sectors within manufacturing: advanced, light, and heavy manufacturing.

EcoVadis scored organizations on 21 sustainability criteria across four themes: Environment; Labor Practices and Human Rights; Ethics; and Sustainable Procurement. Scores ranged on a scale from zero to 100, where below 25 represents high risk, 25-44 represents medium risk, above 45 represents good performance, and above 64 is considered advanced. In this year’s index, 57% of companies achieved scores of 45 or higher.

Regulation Is Pushing Manufacturers into Sustainability

There are a number of factors that press on manufacturers to move toward sustainability. Some come from inside – such as improving efficiency – while others come from outside – such as regulations. “We’re seeing sustainability track with how manufacturing is regulated,” Pete Rau, director and sustainability expert at EcoVadis, told Design News. “Connected to that is the recognition that sustainability equals improved operability. We’re also seeing product design efficiency as well as the control of energy and water use.”

The technology of data is another factor that brings inefficiencies to light. “We find that underlying sustainability is access to information. Whether it’s business-to-business or consumer, we have more information about what companies are doing,” said Rau. “More accountability has been placed on factories from corporate headquarters. The factory floor winds its way in the news, online, and social media – not just negatively, but also positively.”

Six Sigma Still Matters

Part of the push to sustainability comes from the continuous improvement movement that goes back decades. Six Sigma Certification necessitates the wholesale cleaning up of manufacturing processes. “It’s absolutely correct that Six Sigma is a factor. It comes back to bottom-line efficiency,” said Rau. “I’ve been working in sustainability for seven years and what I’ve seen is the practicality of sustainability. Ten years ago, it was Kumbaya. Now it’s just practical. I’ve always been a pragmatist, and what we’re seeing is best operational management.”

The Six Sigma tie-in shows that most moves to sustainability involve an improvement in overall operation. “The business case is relatively easy to make. It’s resource efficiency,” said Rau. “You’re seeing it on the social side as well. Improved operations have an impact on employee attention and employee engagement. Workers want to feel they have a connection to the work and that the work is having a positive impact on the environment.”

Heavy Manufacturing Is Keeping up with Advanced and Light

One surprising reveal from the research is that heavy manufacturing is carrying its weight alongside advance and light manufacturing. “It looks like heavy is keeping up with light and advanced manufacturing. That has to do with the social impact of heavy manufacturing,” said Rau. “It has to do with the performance and sophistication of their management approach and the amount they have to manage. Sustainability measures reduce risk. In heavy manufacturing that’s a large consideration,” said Rau.

Differences in Advanced, Light, and Heavy Manufacturing

Here are the standings EcoVadis have given to three types of manufacturing: advanced, light, and heavy:

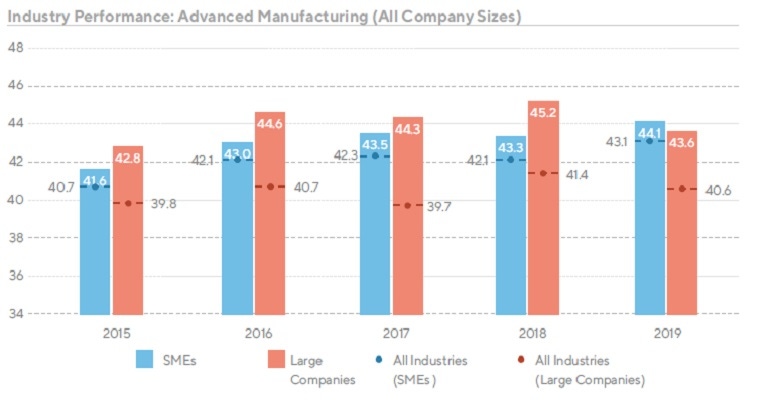

Advanced Manufacturing outperforms all other industries in large companies with the help of energy consumption, greenhouse gas emissions, and product efficiency as their driving priorities; small- to medium-sized enterprises (SMEs) have earned a higher average score as compared to their larger counterparts in manufacturing.

Light Manufacturing has seen average scores go beyond world benchmarks and exceed a score of 43 for both large and SME manufacturers. That’s potentially thanks to ongoing scrutiny regarding environmental and social issues.

Heavy Manufacturing companies perform well above the all-industry average, a trend that has continued for the past five years and is in line with trends across all manufacturing sectors.

Differences Across Regions and Supply Chains

North American companies lead in reporting on CO2 emissions, but Europe leads in implementing action. Eighteen percent of businesses in North America participate in direct carbon reporting compared to 15% of organizations in Europe and AMEA. However, year-over-year Europe continues to outperform other regions on sustainability, scoring particularly well in the Environment theme. From a company size standpoint, SMEs significantly underperform large ones in emissions reporting, highlighting the need for engagement strategies that develop management system maturity and guide improvements.

Sustainable procurement continues to lag. Except for sustainable procurement, all theme scores have increased by at least 9% since 2015. While companies are addressing social and labor impacts within their own operations, EcoVadis research indicates they are neglecting the risks that exist among their suppliers. This represents a missed opportunity to drive value and create resilience in the next tier of the supply chain.

Rob Spiegel has covered automation and control for 19 years, 17 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cybersecurity. For 10 years, he was the owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like