Low-code tools put app-building into the hands of the factory’s domain experts at a time when professional developers are expensive and scarce.

October 6, 2020

Manufacturers are seeking alternatives to original programming as they adopt Industry 4.0 technology. In the midst of COVID-19, they are deploying new factory equipment such as cobots to automate their processes. For the most part, cobots don’t require original programming. They require configuration that can be completed by a nonprogrammer. This concept is proliferating beyond cobots to other areas of plant automation. Low-code platforms are offering app-building without programming, offering manufacturers a quick move to advanced automation.

Low code is a visual approach to application development that enables professional and nonprofessional developers to collaborate and rapidly build and deploy applications. According to Gartner, “By 2024, low-code application development will be responsible for more than 65% of application development activity.” A Forrester report noted that “the low code/no-code market is worth $4 billion and growing by 50% annually."

Several companies are offering low-code platforms. Siemens offers low-code through its subsidiary, Mendix. Microsoft, Oracle, Appian, Google, and Salesforce also offer “app maker” tools that are essentially low-code platforms.

Low Code for Manufacturing

Manufacturers are shifting app-building to their manufacturing technology professionals, the domain experts. “Leading manufacturers are using low-code for IoT solutions because it enables domain experts to co-create proactive, contextual and personalized applications,” Sheryl Koenigsberg, global director of product marketing at Mendix, told Design News. “Low-code makes it easier for the team to digitalize workflows across OT and IT, enhance factory automation initiatives, and support field operations teams.”

Companies are turning to low-code to bridge programming the gap and accelerate application creation. Low-code’s graphical interface and model-driven logic allow people who have no or limited coding experience to get involved in developing applications. Yet some companies are getting blow-back from IT. In many cases, the IT group is reluctant to support low-code because they don’t see the technology as enterprise-ready. Meanwhile, low-code providers insist, “We’re ready and we can scale.”

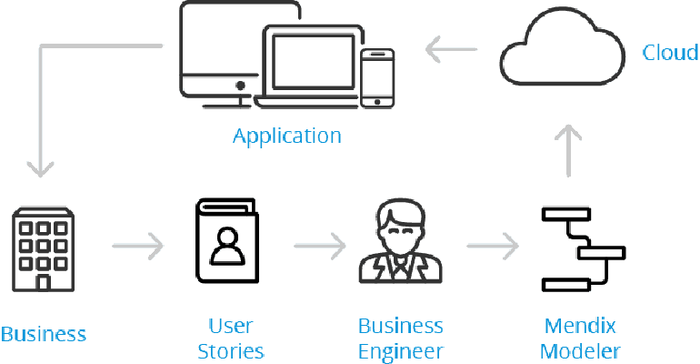

According to Mendix, low-code tools are designed to be quickly adopted by domain experts. “We have seen developers emerge from every facet of the workforce,” said Koenigsberg. “Business analysts who spend their days in Excel or BI tools can start using low-code easily. Industrial engineers for whom model-driven development is second nature find low-code quite accessible.”

Low-code platforms can be used even for those without domain experience. “We have examples of Mendix developers who come from further afield – people with backgrounds as underwriters, for example, bankers, attorneys, and project managers of all types,” said Koenigsberg. “Professional developers master the platform in no time at all. What matters is the desire to learn low-code and the understanding that it can easily solve problems. The background of the user doesn’t matter.”

Low-Code During the Pandemic

In several manufacturing sectors, the COVID-19 pandemic forced companies to innovate quickly, whether it was because they had to produce medical equipment or simply that they were trying to keep up with consumer demand. “In 2020, digitalization became table stakes. Companies in all industries have been eager – desperate, even – to find ways to get software created quickly,” said Koenigsberg.

Automation experts have had to revamp their operations overnight. “Low-code is the best way to do that. During the global pandemic, enterprises woke up to find that they suddenly needed to vastly accelerate their efforts to digitize internal processes, reach customers on all kinds of devices, and offer new AI-driven products and services,” said Koenigsberg. “You couldn’t possibly hire all the different skill-sets necessary to deliver that range of applications fast enough. Enterprise low-code offered a single approach to developing broad solutions with a small, non-specialized team.”

Given its recent popularity, it’s surprising that low-code development has been around for many years. “Rapid application development tools have been in use for several decades,” said Koenigsberg. “Today, the visually abstracted approach to software programming and development is seeing widespread enterprise adoption throughout every sector of the economy.”

Bringing Developers and Domain Experts Together

Another benefit is the ability for developers and domain experts to work closely together. “Enterprise low-code platforms let professional developers co-create software alongside domain experts and business stakeholders,” said Koenigsberg. “They get validation of design and requirements along the way.”

The shift to low-code applications can change the culture of automation development. “Low-code transforms how organizations deliver software. It’s bigger than non-programmers developing applications,” said Koenigsberg. “What low-code offers is a holistic approach that enterprises can take to address the acute shortage of development resources. With enterprise low-code, domain experts can be part of the development process. Plus, the solutions they build align with established guidelines around quality, scalability, and governance.”

Rob Spiegel has covered automation and control for 19 years, 17 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cybersecurity. For 10 years, he was the owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like