The Industrial IoT Consortium, formerly the Industrial Internet Consortium (IIC), considers ways to really deploy the industrial IoT or IIOT.

September 14, 2021

Stephen Mellor

The industrial internet is the term given to the internet of things (IoT) when applied in industry. These industries vary wildly, from manufacturing to health care to smart cities, transportation and mining. The technologies used in the industrial internet (small, cheap sensors and actuators, low-cost processing and data storage, smart devices, and connectivity) are the same as in consumer products, but the business drivers are different. In consumer IoT, quality must be adequate, whereas, in the industry, it must be high. Security is always an issue, but in the industry, it is critical—life, limb, and the environment are at risk. And in consumer IoT, the price-point should be relatively low, while in industry, cost matters less than the return on investment. Those returns could be in the form of improved asset efficiency (predictive maintenance, for example), new products, and new markets. These last can be transformative.

The industrial internet is deep (from control loops for machines and robots to provisioning multiple devices and orchestrating them to big data and edge computing) and covers multiple industries. It is so large that one company could never dominate it.

In 2014, the industrial internet market was relatively small, and it could be classified as a “blue ocean” market. Coopetition and collaboration were the driving forces, not competition. This lead to the creation of the Industrial IoT Consortium (IIC).

Backstory

The Consortium grew rapidly from five founders to over 270 companies in 35 countries. Over these last seven years, we have published many papers that have laid the foundations of the industrial internet and the market. This has been supported by 35 IIC testbeds that have tested new technologies, new business models, and existing technologies used in different ways. From these testbeds, our members have learned a lot. Over the years, the number of new testbeds slowed, and some testbeds have finished their work and moved into deployment, which was the unstated goal: to build on these foundations and then focus on deployments. But our original mission focussed on building the market, so a shift is in order.

Large industrial companies have long financial lifespans. They are used to making big bets over many years. The average industrial installation is 19 years old. Return on investment is key. Airbus, for example, has not yet made money on the A380, despite the first flight being 16 years ago. This is different from IoT projects where “fail fast, often fail” are watchwords for technologies we have little experience with, especially when we must make them work together.

The software can be updated quickly, which flies in the face of industrial-organizational caution, which is accustomed to year-long safety and compliance checks cycles. Then we have risk. Is a small productivity improvement worth the risk that the installation could be down for weeks?

So we must be cautious and think carefully about motivation and risk. Technological enthusiasm is not a sufficient reason to risk losing production. We should identify where the company in question is feeling pain. Is it frequent unscheduled maintenance? Or the need to expand services? Pain could be in company operations, productivity or economics, human health and safety, customer satisfaction, and product quality. Pain produces motivation.

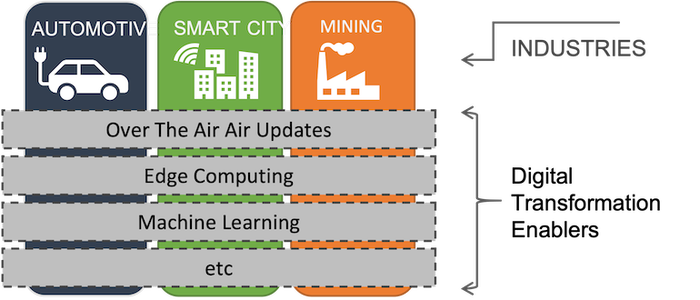

Once we know we have a problem to solve and the motivation to address it, we can apply industrial internet technologies, the set of tools and technologies that make up the technology stack that is the industrial internet. These can enable digital transformation and transformational business outcomes, so we call them digital transformation enablers.

Game Plan

Digital transformation is the final step in a process of digitization to get data in the business from paper to machines and thus available to all. Then digitalization, which uses digitized data in the company process, enables standardization of operations. Digital transformation builds on digitization and digitalization to create new business concepts and to design new applications. (See the Digital Transformation in Industry white paper.)

But let’s not get ahead of ourselves. The first thing we need to do is identify the pain (which leads to motivation) and which digital transformation enabler we can apply. We could, for example, use over-the-air updates to update software in an automobile. Tesla’s update during Hurricane Irma extended battery life in the car when the time was of the essence.

We can also use over-the-air updates in a smart city. A smart city could have many thousands of devices controlling lighting, traffic, and so on. It would be costly for a technician to do this.

In a factory, sending data to a data center to get a result to control an actuator can take too long. Better to put computing and data storage “near” to where it is used. The same, of course, applies to automated vehicles. This is “edge computing,” another digital transformation enabler.

In short, there is a matrix of industries against digital transformation enablers, and each intersection is a deployment.

It is this need to span verticals and to focus on deployment that triggered a rebranding of the IIC. At seven years old, in technology years, we are at best “mature.” Moreover, the term “industrial internet” never really took hold, and “industrial” (especially in Asia) connotes manufacturing, even though IoT can be applied in multiple industries. We need to maintain “IoT” for continuity Hence the rebranding to Industry IoT Consortium.

We have created an industrial internet market; now, we must look to deployments. To do that, we must identify the intersections between digital transformation enablers and the pain felt by technology end-users. Then we must reduce both their perceived and actual risk. That is why we modified Industry IoT Consortium’s mission slightly to become: “To deliver transformative business value to industry, organizations, and society by accelerating adoption of a trustworthy internet of things.”

We feel younger already!

Stephen Mellor is the Chief Technical Officer for the Industry IoT Consortium, where he aligns groups for business, technology, trustworthiness, and industry for the Industrial Internet.

You May Also Like