Advanced manufacturing in the life sciences requires components with stringent performance and quality standards.

The digital revolution, also known as Industry 4.0, is well underway. Manufacturers worldwide are experiencing an era of unprecedented efficiency and growth spawned by the development of increasingly complex smart machines. For manufacturers in the life sciences sector, this equipment requires the mass production of precision components designed and built in a highly regulated environment under stringent performance and quality standards.

Such manufacturing facilities require precise speed control to ensure life-saving devices such as ventilators, anesthesia devices, and insolation valves deliver reliable results. One such company helping medical device manufacturers adopt the factory of the future and ensure production units deliver compliant and dependable performance is Norgren. Contributing to the medical field's advancement, they design, develop, and manufacture fluidic components and assemblies.

To spotlight the critical need to continue progress toward and adoption of the smart factory and the precision components that make Industry 4.0 a reality worldwide, Informa Markets – Engineering, the organizers of the industry-leading Medical Design & Manufacturing (MD&M) and BIOMEDevice events and publisher of Design News, will present MD&M | BIOMEDigital, a new virtual conference, and exhibition for medical device engineers and manufacturers driving progress and innovation in medtech and biotechnology.

I recently enjoyed speaking with Rachel Lahr, director of sales, Life Sciences, Norgren. The company will be exhibiting at MD&M | BIOMEDigital and shared a sneak peek into what attendees can look forward to learning about at their virtual booth.

Medical devices and machines are increasingly complex, requiring cutting-edge design and components to continue contributing to research advancement that leads to a healthy global society. At Norgren, you have been enabling manufacturers to launch market-changing products for the past 30 years.

Hayley Haggarty, group event director, MD&M and BIOMEDigital: Can you speak to your product portfolio in the life sciences sector?

Rachel Lahr: With over 30 years experience in the life science sector, Norgren is one of the most recognized names in the custom design and manufacture of precision fluidic control components and assemblies for the OEM instrument manufacturers in the medical device, biotechnology, diagnostic, and analytical instrumentation. Our market-driven product portfolio is designed for the industry's precise control, repeatability, and safety needs with a specialty in miniature solenoid valve technology, microfluidics, precision liquid handling solutions, and analytics instrument solutions. Our platform products and technologies and customized fluidic solutions include solenoid valves, pinch valves, rotary valves, pump technology, syringes, electronic controllers, and integrated manifolds and subassemblies.

Renown for high-quality and robust designs, our products reduce OEM devices' size while enhancing accuracy, throughput, and fluid control performance. Our components are designed for optimal 'size to performance' ratio with smaller footprints, higher repeatability, and lower operating power. Our understanding of the market trends, engineering challenges, and regulatory standards gives us the capability to provide complete, OEM-specific, integrated platforms that deliver value. With an established sales and service network in 75 countries, our dedicated life science sector teams work together around the world to provide Breakthrough Engineering for our customers.

Hayley Haggarty: Your solutions keep instrumentation functioning across many critical applications, including analytical instrumentation, biotechnology, diagnostic instrumentation, and medical devices, all requiring increasing accuracy and handling levels. How is Norgren paving the way for future innovation?

Rachel Lahr: Fostering and nurturing an innovative culture is essential to our business model and critical to addressing our customers' future needs and the life sciences industry. At the forefront, this means customer centricity and being highly adaptable and agile in solving problems for our customers. Building close relationships with our customers and collaborating with them early on allows us to anticipate and respond proactively to emerging trends, unanticipated market shifts, and other market potential. Through these close and collaborative relationships with our customers, we gain a deep understanding of their engineering needs and then mobilize our resources and expertise with dedicated teams to deliver bespoke products and solutions. Agility allows us to adjust to changing needs while tailoring products to specifically meet a customer's needs.

In the wake of the pandemic, this innovative culture and mindset gave us a competitive advantage in addressing the global demand to deliver critical components significantly shortened for ventilator and vaccine production customers without disrupting the business. By responding rapidly to our customers' essential needs, in turn, we have developed trusting and long-lasting relationships. Equally crucial to paving future innovation is the continuous improvement and expansion of capabilities with new technologies. At Norgren, we are invested in growth strategies to identify new areas of opportunities and proactively keep our eye out for cutting-edge technologies shaping the future of life science. We highly engage with customers to understand the impacts of these trends and technologies so that we can meet their needs at precisely the right time.

Hayley Haggarty: You are exhibiting at MD&M | BIOMEDigital, the medtech and biopharma's leading virtual event. What products, solutions, and industry advancement can attendees look forward to seeing and learning about at your booth?

Rachel Lahr: At Norgren, we are more than a components supplier. We are innovators and problem-solvers that understand the goals and needs of the diverse life science market. As an exhibitor at MD&M | BIOMEDigital, attendees will be able to explore our breakthrough engineering innovations and capabilities that contribute to thousands of people's health and well-being every day, or as we call it, Breakthrough Engineering for a Better World. Visitors will get a glimpse inside our expansive product portfolio of solenoid valves, pinch valves, rotary valves, pump technology, syringes, electronic controllers, and integrated manifolds and subassemblies and learn how these products are used in everyday life-saving applications. More importantly, visitors can learn first-hand how Norgren helps solve critical problems for the life science industry through integration, miniaturization, and single-use fluid control.

We'll also be holding a 30-minute Tech Talk on Optimizing Integrated Manifold and Valve Systems for Life Science Devices – which shouldn't be missed! Our experts will discuss the rapid advancement of biomedical devices driving increased complexity in fluid control systems and ensuring high performance of manifold and valve designs while keeping in mind crucial considerations such as cost, size, and manufacturability.

Hayley Haggarty: What makes Norgren stand out from competitors in this increasingly technical market?

Rachel Lahr: In an increasingly technical market, Life Science manufacturers continually seek solutions to reduce complexity, decrease labor time and costs, and maintain confidence in the reliability of their multifaceted systems. At Norgren, we provide this value and more through product integration. As a single-source supplier, Norgren offers a comprehensive range of products with full system integration capabilities.

These turnkey solutions in the form of fully integrated, assembled, and tested products provide assurance that these complex systems work properly and cohesively over time. The value of integration is a comprehensive and cost-effective solution that simplifies installing, training, and maintaining the system. Our engineering experience with processes and operations combined with intimate knowledge of the manufacturer's machines allows us to wrap this expertise around the customer to solve their problems and very quickly resolve any engineering issues that occur along the way. Additionally, the financial benefit of integration allows customers to reduce or maintain costs and more accurately track their return on investment. These capabilities have driven business and provided Norgren a competitive advantage in the marketplace.

Hayley Haggarty: What excites you most about participating in the upcoming virtual event?

Rachel Lahr: Norgren is delighted to take part in the MD&M | BIOMEDigital virtual event. As a world-class supplier to the life science industry, including the medical device, analytical instrumentation, diagnostic instrumentation, and biotechnology segments, we are excited to unite with other leaders and innovators in life science manufacturing. We look forward to engaging with current customers and connecting with individuals and companies seeking new technologies and innovative solutions.

We're looking forward to demonstrating our capabilities and sharing how we provide tremendous value to our customers with our extensive product portfolio and expertise. We are also looking to participate in sharing ideas and learning about trends and new technology advancements that are creating needs in the market and establishing new partnerships to meet those needs in the near future.

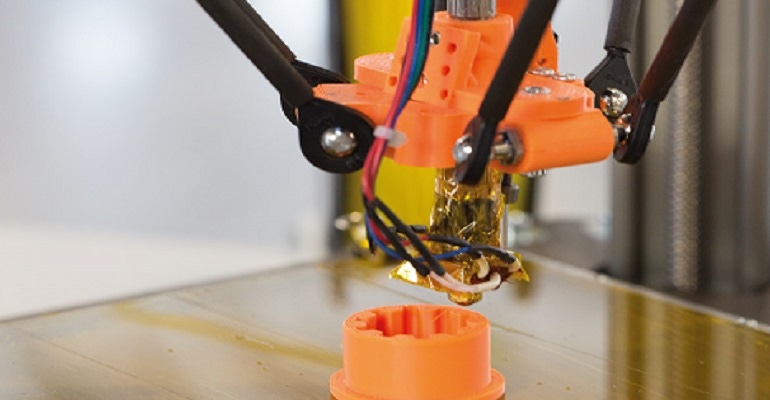

Taking place April 6 and 7, the virtual event will provide a unique meeting opportunity for the global community featuring a virtual expo floor with more than 100 companies driving frontline product innovation. The conference will include a robust agenda offering technical sessions curated around today's challenges, from integrating new materials into the 3D printing process to showcasing innovations in micro-molding medical devices.

Register here and access exhibitor profiles, exclusive networking opportunities, and technical sessions that matter to you.

To schedule a meeting with Norgren at MD&M | BIOMEDigital, please register for the event and reach out to Rachel Lahr, director of sales, Life Sciences at Norgren: [email protected].

About the Author(s)

You May Also Like