‘Cavatappi’ technology could out-perform human skeletal muscles in some instances.

June 2, 2021

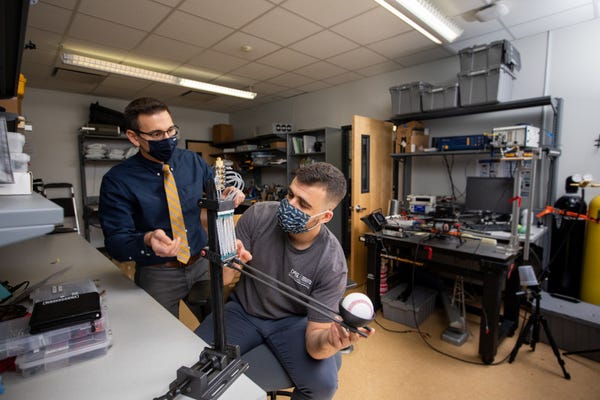

Researchers have developed artificial-muscle technology that can potentially even surpass human movement and be applied to robotics and biomedical applications.

A team of engineers from Northern Arizona University developed the high-performance technology, which they said cannot only enable allow for human-like motion in certain robots because of its flexibility and adaptability but even outperform it.

Calling the technology “cavatappi artificial muscles” because of their similar appearance to Italian pasta, the technology has a coiled, helical structure, which allows them to generate more power than comparative technologies.

In fact, in tests, the muscles demonstrated work and power metrics 10 and five times higher, respectively, than human skeletal muscles, with the potential for even higher performance, said Michael Shafer, an associate professor at NAU who collaborated on the research with Professor Heidi Feigenbaum and graduate student researcher Diego Higueras-Ruiz in NAU’s Department of Mechanical Engineering.

“Given the hydraulic or pneumatic activation source, these devices have the potential to substantially outperform similar thermally activated actuation technologies regarding actuation bandwidth, efficiency, modeling and controllability, and practical implementation,” researchers wrote in an abstract for a paper published in the journal Science Robotics.

How It Works

The technology for the muscles are based on twisted polymer actuators (TPAs), which historically have been slow to actuate because they had to be heated and cooled, and only work at an efficiency of about 2 percent, Schafer explained.

To solve this problem, researchers used a pressurized fluid to actuate the cavatappi artificial muscles that are fabricated from inexpensive polymer tubes, he said. “These devices respond about as fast as we can pump the fluid,” said Schafer.

The actuation works from the design of the movement of the tubes. First, the tubes are drawn, which “enhances the anisotropy in their microstructure,” researchers wrote in the abstract. Then, the tubes are twisted, which can be used as a torsional actuator. For linear actuation, the tubes are helically coiled.

“After drawing and twisting, hydraulic or pneumatic pressure applied inside the tube results in localized untwisting of the helical microstructure,” researchers wrote. “This untwisting manifests as a contraction of the helical pitch for the coiled configuration.”

Advantages and Future Use

Schafer said that the key advantage to the actuation of the artificial muscle over comparable technology is its efficiency. “We have demonstrated contractile efficiency of up to about 45 percent, which is a very high number in the field of soft actuation,” he said in a press statement.

Moreover, the cavatappi artificial muscle contracts more than 50 percent of its initial length and can exhibit a maximum specific work and power of 0.38 kilojoules per kilogram and 1.42 kilowatts per kilogram, respectively.

The team plans to continue its work to develop the muscle to achieve even higher performance results in the future, Schafer said. Applications for the muscle not only include soft robots but also more conventional robotic actuation for walking robots. It also could be applied to technologies such as exoskeletons or prostheses, he said.

“We expect that future work will include the use of cavatappi artificial muscles in many applications due to their simplicity, low-cost, lightweight, flexibility, efficiency, and strain energy recovery properties, among other benefits,” said Shafer.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time, she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like