February 18, 2015

AC servo systems have long been the workhorses of industrial automation, but it's time to start thinking of them as thoroughbreds. Thanks to ongoing advances in control algorithms and processing power, the best AC servo drives can now exert degrees of control that would not have been possible even a year ago.

Not every AC servo drive, however, has what it takes to qualify as the best, making it difficult to bring about significant improvements in line speeds, positioning accuracy, vibration control, and other important automation objectives.

Which features should you look for in advanced AC servo drives and which applications do these features target?

Boost frequency response

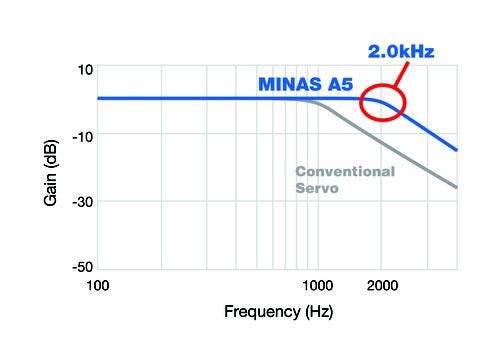

The top speed of a motion system and its ability to respond quickly to positioning commands obviously depend, at least in part, on the servo drive's frequency response. AC servos can vary widely in their frequency responses. The fastest systems today can achieve a frequency response of 2.3 kHz, while more typical response value would be on the order of 1.0 kHz (See Figure 1).

Click on Figure 1 below to start the slideshow.

This extra speed can come in handy in any application that benefits from enhanced positioning accuracy and repeatability, such as semiconductor processing equipment. Speedy motion systems can also improve the productivity of fast-moving processes. Packaging lines are a prime example.

Beyond speed and positioning advantages, a fast frequency response also tends to reduce vibration, which can be important in just about any moving machine application.

Maximize resolution

Thanks to breakthroughs in signal processing, the resolution available from incremental encoders has recently improved exponentially.

Panasonic's new MINAS A5 AC digital servo drives, to take a leading example, use proprietary signal processing methods and a dedicated serial communications bus to get 1.04 million pulses per revolution from a 20-bit encoder. Compare that ultra-high resolution to the 2,500 pulses per revolution that a conventional AC servo drive would get from the same encoder.

This support for high encoder resolutions translates directly to smooth, vibration-free motion and ultimately helps increase positioning accuracy. Machine tools, textile machines, and semiconductor equipment can all get a significant performance boost from the additional resolution.

Simplify set up with advanced auto-tuning

One often overlooked, but increasingly important, differentiator among AC servo drives is ease of use. While some controls engineers have the knowledge and time to tune PID loops manually for each and every application, more advanced drives have supplemented manual tuning with automated tuning capabilities that make servo drives easier and less costly to set up. Equally important, auto-tuning can also improve servo performance by eliminating tuning errors and achieving a level of control not easily reached by manual tuning.

Consider the auto-gain tuning in Panasonic's MINAS A5 servo systems, for instance. Based on changes in stiffness alone, it can calculate the relevant inertia ratios, resonance frequency, oscillation, and gains. To set up and operate the system, users simply single tuning parameter that corresponds to a specific operating goal -- including positioning, vertical axes, high-friction axes.

Variants of auto-tuning have become commonly available from many automation vendors, though you will notice differences in how well and how quickly different auto-tuning algorithms will work.

Reduce cogging torque

Even the most advanced control algorithms do not adequately compensate for cogging torque, which leads to uncontrolled vibration and positioning errors. The right type of motor, however, can go a long way in reducing cogging torque.

Increase high-performance filters

Most moving machines will benefit from a reduction in noise and vibration, both for the longevity of the machine components and also for the machine to operate at its top speed. Notch and damping filters are two of the key control strategies for reducing vibration.

Notch filters reduce the noise and vibration caused by resonant frequencies. MINAS A5, for the first time, has four adaptive notch filters covering a frequency range from 50 to 5,000 Hz. Available in both auto- and manual-tuning modes, the filters can reduce noise and vibration due to resonance in applications such as semiconductor or packaging machines.

Advanced servo systems should also include damping filters, which remove the natural vibration frequency from the command signal. The result is drastically reduced vibration, particularly when a motion axis comes to a stop or settles on a position (See Figure 3).

Not all AC servo drives are created equal. But if you select one with the right combination of combination of speed and smarts, you can make all kinds of industrial machines run faster, smoother, and better.

William Nieves holds Masters of Science in electrical engineering and computer engineering from the New Jersey Institute of Technology. He is active in the fields of industrial networks, advanced control systems, and mechatronics. He is also a member of various IEEE societies.

About the Author(s)

You May Also Like