November 25, 2013

Medical diagnostics are a part of everyday life, whether going to the doctor for a routine physical and blood work or heading to the emergency room. Doctors rely on the results from medical analyzers to inform us of changes in our body or administer life-saving medicine. The accuracy and speed of the analysis is critical for these machines and the responsibility for this falls on the motion control in the machine.

A medical diagnostic machine takes a sample and analyzes it for a variety of items or a specific item. The sample travels through various stages of the machine, from preparation to final analysis, utilizing motion control in all of the functions. The test tube (or well) must move into position for the sample to be drawn. A needle is lowered into the test tube (or well) to draw out the sample and reagents are then added to the sample. Motors control all of this motion and we will talk about the specifics of each of these applications.

Main motion functions in medical analyzer

Samples reside in test tubes (or wells), placed in trays that can hold up to 96 tubes or wells up to 1,024. The tray is loaded into the sample preparation stage and the contents of each tube are loaded into the computer or identified by a bar code label on the test tube. Conveyors or linear stages move the pipette into position for the sample to be collected. Since the test tubes are small in diameter, the precision of the movement is critical for the sample to be taken quickly. The faster the sample is processed through the machine, the quicker the results can be provided to the doctor.

Once the pipette is in position for the sample to be drawn, it moves down into the test tube (or well) to draw the sample. In many machines, multiple pipettes operate at the same time. The movement required by the pipette is linear, driving the pipette downward and then pulling it back up to its starting position. Proper timing is required as the pipette must reach the proper depth in the sample to draw the required amount, plus wait in position for the sample draw to be completed.

With the sample drawn, the next step is the analysis. Analyzing the sample involves introducing reagents via pumping or pipetting operations. The pumps used range from peristaltic to syringe, depending on the requirements of the sample. Once the analysis is completed, the sample and any additional waste must be removed from the system. Again this is achieved via a pumping or pipetting operation.

Technical specifications for each axis

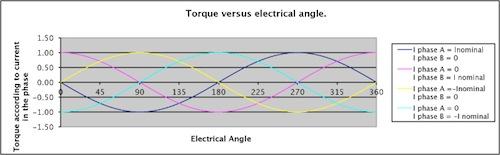

We will now take a look at the technical specifications for each of the functions. As mentioned above, different types of pumps are utilized throughout medical analyzers. The pumps are defined by their flow and volume capacity and are selected based on the needs for each function. A motor, typically Brush DC, Brushless DC, or Stepper, provides the mechanical power to operate the pump. Motor selection is based on several criteria:

Technical specifications -- torque at speed, efficiency, and noise

Life required for the application

Cost

Pump OEMs can interchange the motor technology to tailor the pump to the specific axis requirement. Long life marries well to brushless technology and steppers. Since multiple pumps can be used in a medical analyzer, you can see all three motor technologies on pumps throughout the machine.

About the Author(s)

You May Also Like