November 2, 2011

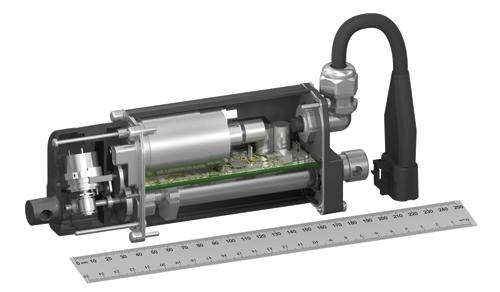

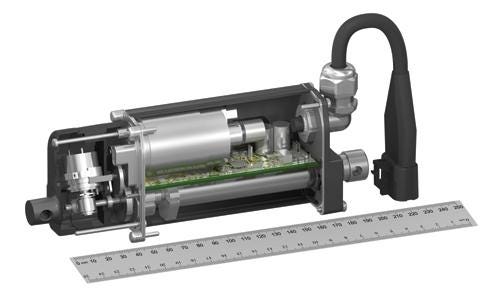

Integrated actuators incorporating more advanced controls and broader network connectivity options are finding their niche in applications where the simplicity of an all-in-one, actuator-motor-control package fits cleanly into new machine designs. The key is a single mechanical actuator-motor with onboard electronics that can provide both a broader set of controls and the simplicity of an integrated solution.

"The sweet spot for integrated solutions is where distributed power and control offers a significant advantage," says John Walker, vice president for Exlar Corp. "Mobile equipment is an example of applications where typically there are no traditional control panels to house the drives and controls for electric actuation on a vehicle. Actuators on mobile equipment are often powered from the vehicle's batteries, and having a compact controller and power device right on the motor and actuator is a big benefit."

A typical packaging machine isn't always the best fit for the integrated actuators. Packaging machines often use a traditional control panel with PLCs and drives and don't have long distances from the drives and controls to the actuators. Integrated technology provides a larger benefit when there are longer travel distances between the central controller and the actuator or in applications that don't traditionally have control panels at all.

Control of independent, single-axis machine functions is an ideal candidate for distributed motion. Traditional hydraulic and pneumatic cylinder applications are inherently standalone, single axis, and provide point-to-point motion. In replacing fluid power solutions with electric linear actuators, coordinated motion is typically less common. These types of standalone, point-to-point applications are well suited for, and often solved with, integrated actuators.

Walker says that developing additional network communication solutions is an important factor for distributed motion products. One of the big advantages of the integrated solutions, compared to traditional servo systems with separate amplifiers, is the elimination of the expensive motor power and feedback cables. Traditional AC or DC power is still required for the distributed solution, and some applications require a multi-conductor I/O cable, which is far less expensive.

About the Author(s)

You May Also Like