December 6, 2013

The complexity and sophistication associated with today's products can be staggering. A recent article from Strategy Analytics discussed how autonomous vehicle products and technology are advancing rapidly. With radar, lidar, and camera-based systems now appearing on mainstream vehicles, "a realistic prospect that some form of self-driving car could be on the road within the next 15 years or so."

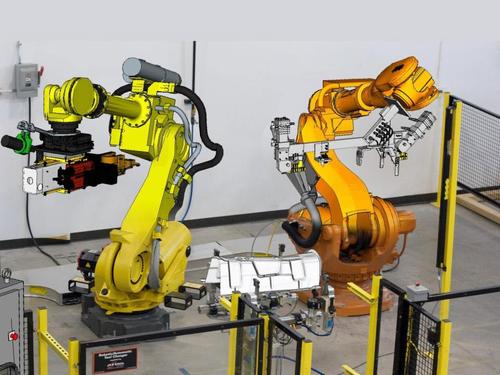

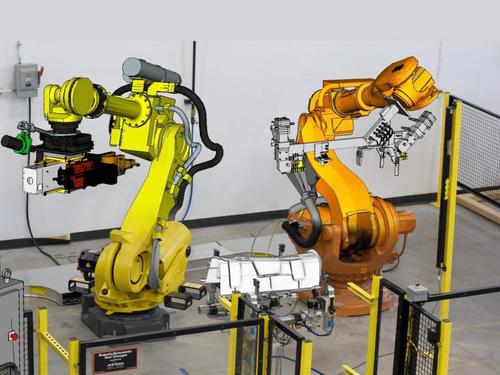

The introduction of complex systems is not just in the automotive sector. In aerospace we see drone aircraft with advanced composite materials. In consumer electronics we see wearable computers. In the machinery sector we see robotics that dynamically adjust their actions and strategies. And in the medical industry we see implanted micro-electronics to help people's hearing and vision.

All of these products require mechatronics systems. In essence, mechatronics systems require the integration and management of the software controlling a specific function, which runs on a piece of electronic hardware, whose signals are transmitted via electrical wires, while all fitting within and conforming to the environmental constraints of the mechanical package. Whether you refer to this as "mechatronics" or "electro-mechanical design," the rapid increase in complexity requires the integration of these domains and the intelligent management of their interdependencies.

Given the growing cross-domain complexity issues, engineers struggle with how to manage, find, and reuse design data across multiple sites, domains, and processes. The proliferation of product configurations has made it much more difficult to understand all the cross-domain and product configuration relationships and dependencies needed to intelligently assess the impact of the inevitable requirements or design changes. It's also difficult to collaborate within and across domains and functions to simulate and analyze system performance in a timely manner and then accurately validate the design's readiness for manufacturing across all domains.

Improving product quality, while accelerating product development, requires an integrated product lifecycle management (PLM) approach to design management that combines mechanical, electronics, software, and simulation data and processes with product requirements into a single collaborative environment.

Requirements definition and management

To deliver testable, high-quality products, developers must fully understand the requirements and share a common vision of the product with other members of the development team. There must be a clear association of the individual requirements to the physical design. By using PLM to manage and allocate requirements, design teams can use this information to direct their implementation strategies and ensure they address all the product's requirements.

While defining their implementation strategies they can also start to develop and associate the required test cases and establish the test/simulation constraints for each part or sub-system needed to validate the design. In addition to capturing and managing requirements, PLM enables engineers to link individual requirements at the subsystem or component level, providing the traceability needed to assess the impact of proposed changes on the design. The end result of this level of mechatronics requirements associativity is that everyone involved in the entire product lifecycle sees the overall system context and understands their domain's specific product objectives.

About the Author(s)

You May Also Like