August 7, 2015

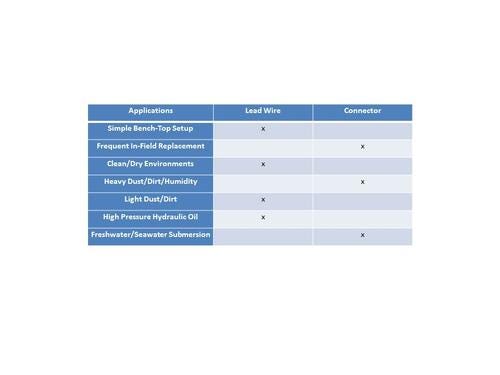

When do you use lead wires and when do you use connectors when providing the electrical connection of an linear variable differential transformer (LVDT) position sensor? Connectors and lead wires provide the electrical connection between the coils of an LVDT position sensor and signal conditioning electronics. Choosing between a connector and lead wires, when specifying an LVDT or other sensor, often depends on the application and its environment. Below are some helpful tips to guide you in deciding whether to specify a connector or lead wires for sensors.

Much of the decisions of lead wires versus connectors depends on the environment in which the sensor will operate. “People contact us and say what their application is, and by asking questions, we can find out about their environmental issues – the temperatures, the pressures, or the chemicals surrounding the sensor,” Mike Marciante, applications engineer at Macro Sensors, told Design News. “If we understand the environment, we can get it right the first time. We don’t want them just taking a stab at it. Some people know this inside-out, while others have a new application and need a little help.”

MORE FROM DESIGN NEWS: Ricoh Invents ‘Energy Generating Rubber’ for Flexible Sensors

Generally, using lead wires or a connector is an either-or proposition. They are not often blended unless part of the application is in one environment and part is in another. “If you have a particular environment for a number of tests, typically it’s all one or the other,” said Marciante. “Generally when a lead wire works, you have all lead wires. You only use a mixed bag when there are mixed applications. For a given application, one or the other is better.”

Quality is Critical

Quality isn’t the end-all be-all of choosing lead wires or connectors. Functionality is the more important factor. “Quality is not as important as getting it right. Quality is important, but more important is matching up the right lead wire or connector,” said Marciante. “If the sensor is exposed to radiation, it’s not just a matter of lead wire versus connector. It becomes what type of lead wire or what type of connector.”

He notes that different technologies of connectors or types of lead wires is always a critical factor. “It’s about selecting the best materials for given conditions. With the radiation example, you can’t use any Teflon,” said Marciante. “With lead wires Teflon is very common. But if you have even mild radiation, you have to use a sensor without any Teflon and also use lead wires without Teflon.”

Does Cost Matter?

Cost is always a factor, but low cost lead wires or connectors do not always produce savings. “This is an area where you don’t want to skimp. If you’re going to buy an off-the-shelf LED, the lead wires won’t cost much,” said Marciante. “But if you’re switching out different sensors, it will take more time to make the switch and more cost in rewiring if you’re using lead wires.”

MORE FROM DESIGN NEWS: Sensor Transmits Readings to Wireless Mobile Devices

Reducing expenses by using lead wires instead of connectors may cost more in the long run. “The LVDT sensor may be hermetically sealed, but lead wires are not. If you specify lead wires when you have humidity exposure or splashing or jetting, you may have to replace the sensor more often,” said Marciante.” If you do it with a connector the first time, you will never have to replace it. Same with out-of-doors applications. It is less expensive with lead wires, but eventually you get corrosion.”

We’re heading to Philly! Design & Manufacturing Philadelphia will take place Oct. 7-8. Get up close with the latest design and manufacturing technologies, meet qualified suppliers for your applications, and expand your network. Learn from experts at educational conferences and specialty events. Register today and join us at Philadelphia’s premier industry showcase!

Rob Spiegel has covered automation and control for 15 years, 12 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years he was owner and publisher of the food magazine, Chile Pepper.

About the Author(s)

You May Also Like