July 29, 2015

Linear guides are one of the most important components for the development of automated or computer controlled machinery. They enable smooth and accurate motion for the primary machine functions and can be used on covers, guards, and equipment drawers. 3D printers, CNC routers, and tabletop factories wouldn't function without them.

During the machine development phase, most design engineers will survey existing component manufacturers for standard linear guide products to incorporate into their projects. Invariably, the designer will need to make compromises in their selection process and accept limited design freedom on purchased products. Perhaps the available guides are too large, are the incorrect shape, require additional modifications, and may have unstable supply quantities. Extruded-profile-based linear guides provide design freedom and can incorporate additional features to lower the overall complexity of a machine.

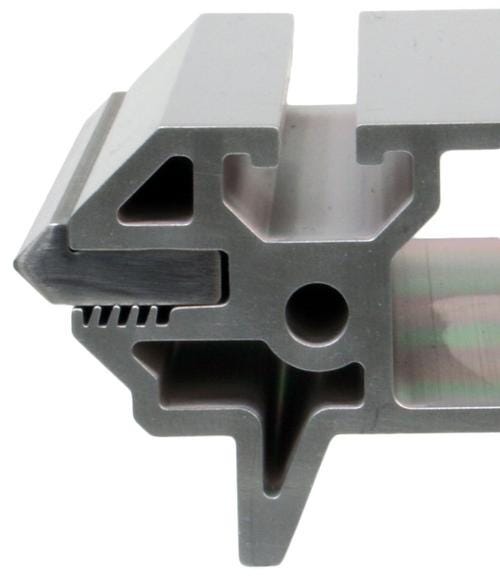

Extruded aluminum profiles come in standardized shapes. They can feature hardened carbon steel, and 90-degree vee guide tracks that are permanently installed into extruded support bases. Recently, track designs were developed to feature a track retention technology where small extruded fingers in the material experience elastic deformation to retain the guide track all along the linear length. This development enables permanent track retention without the need for adhesives or fasteners. This finger retention method can be applied to almost any aluminum extrusion design.

Aluminum extrusions can be produced in an infinite variety of shapes and sizes to suit dedicated purposes.

Extrusions are made when preheated aluminum is forced at very high pressures through the precut opening of a tooling die. The shape of the die opening can be simple, such as a solid circle or rectangle, or it can be complex with multiple holes and thin features. As the material exits the die, it is gently pulled and stretched to counteract twisting and warping as it cools.

There are many grades of aluminum, but the 6000 series is typically used in the extrusion process. Some common grades for these purposes include 6005, 6061, and 6063. Shortly after the extrusion process, they can be heat-treated to improve the material properties. An example is 6061-T6, which is commonly referred to as aircraft-grade aluminum. These materials are rigid and durable, with excellent corrosion resistance. Finishing operations such as anodizing can be applied to the surfaces in any color and with varying layer thickness. Extruded 6000 series aluminum is an ideal substrate for machine bases and linear guides.

The primary motion axes of CNC routers, 3D printers, and other machines can be fabricated from aluminum profile extrusions, and they can be designed to accept hardened steel linear guideway vee tracks to make integrated linear guides. This concept enables design freedom and the ability to incorporate additional machine features into the profile extrusion. Machines produced with this methodology can be greatly simplified.

Lower Overall Cost

The cost to assemble each machine can be greatly reduced because an extruded profile guide eliminates the need to install, align, and adjust separate traditional linear guides. The time and labor required to complete the linear guide installation is reduced because extruded profile guides are supplied as complete subassemblies, with the steel linear tracks already installed.

Sourcing an extruded profile guide will reduce the number of items on a machine bill of materials. The linear guide components are integrated into the extruded beam and are a single component part. This can reduce the amount of engineering documentation, and fewer parts will need to be inventoried and processed during the machine build cycle. Contrast this to the process of installing traditional linear guides using fastener hardware involving torque specifications and adhesive thread-locking fluids. This reduction in complexity can result in a substantial cost savings.

Aluminum extrusions are made in a long and continuous process. Later, they are cut down to usable lengths. A family of machines can be designed around the same extrusion profile, and each machine design can use various lengths for the motion axes. An example would be a CNC router that processes 4-by-8-foot sheets of plywood. The same extruded profile guide could be used for both the X-axis and the Y-axis, typically in an X, X-Prime, Y gantry configuration. One machine of this design would use 20 feet or more of the same extrusion. A single production run of material can yield enough material to produce an entire family of various machine designs.

Extruded profile guides can be manufactured with significant structural rigidity and enable the linear guides to be used in an unsupported fashion over large machine spans. This is ideal for large-travel machines that process large workpieces. Several common machine applications include gantry routers, CNC cutting tables, plasma tables, water jet machines, and laser cutting machines. Although a larger beam design with more cross-sectional area is required, it is not uncommon to span unsupported over 10 feet or more. Beam deflection calculations can be provided as needed.

Intellectual Property

When you design and source an extruded profile guide that is specific to your machine application, you maintain control of the intellectual property. Your competitors will not be able to easily copy your design or simply purchase the same parts that you do from the same suppliers. The extrusion tooling die used to produce your profile is yours. You take control of the supply chain and will not be subjected to backorder or inventory shortages from the manufacturer. Additionally, your design will never be subject to a manufacturer discontinuing the product line.

Brian Burke is a product manager at Bishop-Wisecarver, with more than 10 years of experience in the automation industry and extensive lean manufacturing knowledge. Bishop-Wisecarver Group is a woman-owned family of WBENC-certified companies and one of the most respected names in custom automation solutions and guided motion technology. BWC manufactures, stocks, and distributes guided motion components and systems for linear, rotary and curved track applications used worldwide in industries such as packaging, medical device manufacturing, wood processing, food processing, and semiconductor fabrication.

About the Author(s)

You May Also Like