April 1, 2011

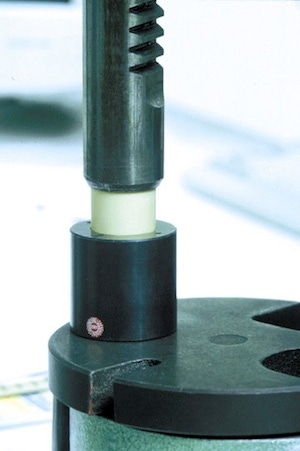

There are three important factors forproper bearing installation. First, you should use an arbor press to press-fitthe bearings. This is the most efficient installation method and will preservethe integrity of the bearing. For example, if you use a hammer, theinstallation of the bearing might be uneven.

Next, ensure your bearing housinghas a chamfer-plastic bearing manufacturer, igus, recommends 25-30 degrees forits bearings-and that it is press-fit with the outside chamfer of the bearingagainst the housing chamfer (for flange bearings, the sleeve portion will havethis).

How to Install and Test a Plain Bearing_A |

Then, ensure yourID-after-press-fit matches your supplier's recommended tolerances for thebearing. All measurement testing should be conducted after the bearing ispress-fit into the housing. Prior to press-fitting, the bearing is oversizedand may not conform to the listed specifications.

Conducting quality checks on thebearings after installation can be done many ways. One way is to use apin-gauge test, also called a "go/no-go" test after press-fitting the bearinginto the smallest specified housing-bore dimension. This will make sure thebearings are within specifications and will work properly once in service. Specifically,a "go" signifies the pin falling through the bearing under its ownweight, while a "no-go" occurs when the pin does not fall through thebearing, or "sticks".

A pin-gauge test is the most accurate quality checkbecause the pin acts like the shaft used in a real-world application and itreveals the inner diameter of the bearing at the smallest points, which is mostcritical to the application.

When using a plastic bearing, apin-gauge test works especially well because the peaks and valleys of thebearing are irrelevant as long as the recommended shafts are able to passthrough the bearing. Over time, as the bearing's self-made lubrication fills inthe peaks and valleys of the shaft and the bearing, an ideal sliding surface isachieved.

While there are other tests thatcan be used to quality-check a bearing, problems can arise when applying thesemethods to plastic bearings. In particular, the use of a caliper should beavoided. Calipers, depending on the level of accuracy, are generally acceptablefor only hurried quality checks. However, depending on the amount of pressureapplied by the caliper or the location of the measurement, it is possible thenumbers will not read correctly. It is more reliable to use a pin-gauge test toavoid unforeseen problems.

How to Install and Test a Plain Bearing_B |

Post-installation Issues

A common post-installation problemis the bearing showing signs of material shave-off at installation. If thisoccurs, check to make sure the housing has the recommended chamfer of 25-30degrees. If using a sleeve bearing (which typically has only one end with anoutside chamfer), match up the bearing's outside chamfer with the housing-borechamfer. If using a flange bearing, the sleeve portion (installed) has theoutside chamfer already. In both instances, also check the housing bore toensure it is not undersized.

Another problem that can occur iswhen the bearing is press-fit into the housing bore is that the IDafter-press-fit is smaller or larger than the recommended tolerances. If thisproblem arises, the following points need to be assessed:

Confirm that the housing bore matches therecommended tolerances (generally an H7 housing bore).

If the housing bore is comprised of a softer metal,like aluminum or plastic rather than steel, it is possible that the bearing ispushing into the housing bore. To compensate, try using a thicker-walledhousing.

Check your shaft tolerances to confirm that yourpin gauges determined during the QC process are accurate.

If the ID of the bearing is undersized, make sureshavings are not in between the bearing and the housing.

Tom Miller is Bearings UnitManager, North America for igus Inc. He can be reached at [email protected]

About the Author(s)

You May Also Like