August 5, 2013

Gearbox selection is not only based on the expected life or strength of the gears and shafts. In certain applications the overhung loads (OHLs) and thrust loads can become the primary reason for the selection.

OHLs are radial forces acting at right angles to the input or output shaft produced by the use of pulleys, sprockets, gears, mixer shafts, hoist drums, or capstans, where the force is considered to be applied at the center of the key. Bearings mounted to the input and output shafts must support these overhung and/or thrust loads in addition to the forces generated by the gears.

Gearbox manufacturers will publish the OHL rating for a gearbox size at a given ratio and speed, however not all L10 bearing lives are equal among manufacturers. A reputable manufacturer will design a gearbox with bearings provided and the L10 life in excess of 5,000 hours -- based on a gearbox service factor of 1.0. A 1.0 service factor is based on a uniform load operating up to 10 hours per day. A gearbox operating for up to 10 hours per day, five working days per week, and 50 weeks per year will accumulate 2,500 hours in a year. Therefore, under a 1.0 service factor, a user should expect a minimum of two years L10 life.

Before we begin to demonstrate the overhung load capacity and L10 bearing life prediction of gearboxes, it is important to have a basic understanding of the forces generated by the gearing and the effect on the life of the bearings. In the case of worm gears, the bearings must react to both separation as well as thrust forces. The magnitude of the separation and thrust forces are dependent upon the input power or output torque the gearbox must handle. Depending on the direction of rotation, an input or output bearing may react to a combination of both thrust and separation force. The OHL ratings found in a gearbox account for the gear geometry forces imparted to the bearings.

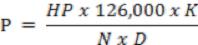

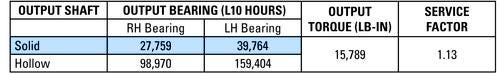

Chart 1 represents the bearing life (L10 hours) for a given size reducer and the effect on L10 ratings considering a change in service factor and output shaft option.

The hours of life shown in the table represent no additional thrust or overhung load. The OHL ratings of the gearbox limit the hours of life to a value recommended by the manufacturer. If the objective of the designer is to achieve 25,000 hours of life, it is important to take into consideration both the input power or output torque and its affect on bearing life, the direction of rotation, and the location of the OHL (right, left, or both sides). A higher service factor may allow for a higher overhung load.

About the Author(s)

You May Also Like