May 14, 2010

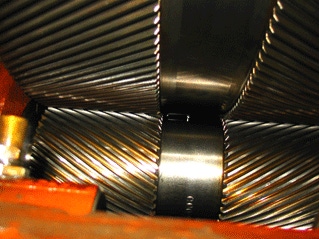

Thegrowth and promise of wind turbines is fueling technology development focusedon the manufacturing of larger, more precise and optimized gearing. The needfor better performance, quieter operation and higher efficiency means that theprimary goal is to limit losses, select proper sealing elements and controlother significant factors that reduce efficiency.

"What's happening right now will be thefuture of the gear industry because of the number of units that will bemanufactured and installed with a main purpose of achieving longer life," says N.K.Chinnusamy, president of Excel Gear Inc. "One way to achieve long life is newtechnology and computer tools that optimize the geometry of the gears and, forexample, optimized root fillet geometry that improves both life and loadcarrying capacity."

One objective is to make componentslighter, and new materials being developed will help achieve that goal. Developmentswith surface finish such as REM technology and electro polishing, some of whichare being used in the racing industry, are having some real significant impact ingear life.

Chinnusamy says there are many challengesin machining gears for wind turbines. Gears for wind turbine applications aretypically large in diameter and have wide face widths, requiring very exactingmaterial composition and heat-treatment processing. The gear design must be optimizedto insure low rolling resistance and long life, to minimize costs ofmaintenance, down time, and repair of the gear box assemblies once they havebeen commissioned in the field. Every step in the manufacturing phase of thesegears must be carefully processed, documented and controlled to achieve thehigh quality, consistency, accuracy and reliability that is demanded foroperation in these environments.

The use of carburized steel for these gearsis common and the associated heat treatments and stress-relief operations haveto be exacting to minimize part distortion and growth, as well as to achievethe proper metallurgical properties required. Often, a preheat treatment of theforging or bar stock is necessary on large gears to minimize part distortion.

Chinnusamy says heat treatment cancause cracks, so careful processing with predetermination of stock allowancefor grinding and final case depth must be considered. Inspection for crackswith magnetic particle inspection and for grinding burns utilizing nitaletching is an important inspection tool. Plus, off center crown grinding of thetooth geometry may be needed to properly distribute the load on the gear teeth.

To efficiently make gears for thisapplication, Chinnusamy says there are often modifications needed in thetooling. Rigid, heavy-duty hobbing machines are needed for the coarse pitchgears, using roughing hobs or gear milling (gashing) cutters. Likewise, coarsepitch diamond dressing rolls and special grinding wheel abrasives are requiredfor the large, high-accuracy gear grinders to produce efficient, accurateresults and to prevent grinding burns and cracks.

Cutting fluids used must have theproper viscosity, the right amount of extreme pressure additives, and must bedirected to the exact location of the work piece and cutting tool interface tomaximize results. These fluids have to be routinely sampled and adjusted foroptimum results.

In building the gearbox, it's alsoimportant to establish the correct bearing clearances/preloads and propergearbox operating temperature that is critical to long life. Sophisticatedmeasuring techniques with bearing inspection gages can only insure theseresults. The type and method of lubrication and proper sealing weighs heavilyon the performance of a gearbox. The verification of gearbox performancethrough computerized analysis and testing is a crucial step to insuring longlife.

"The critical factor here, as with allsimilar power transmission applications, is that the gears are properlydesigned and manufactured," says Chinnusamy. "The other mechanical components that make upthe assembly, along with the gearing, must be applied and designed so theoverall system performance does not have any shortcomings that could affect theperformance and life of the unit."

About the Author(s)

You May Also Like