Power & Energy

European Union sustainability regulations for manufacturers

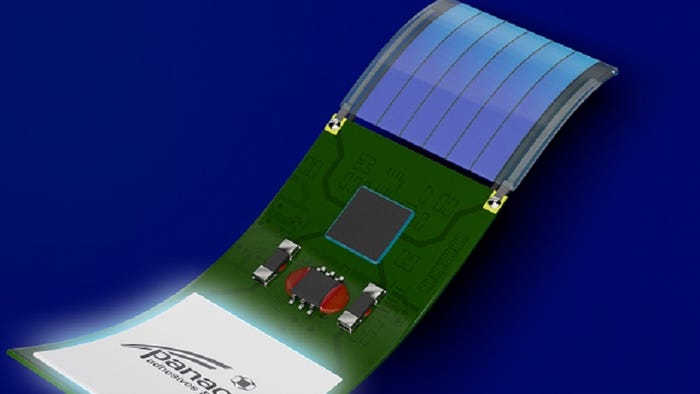

Automation

The EU�’s Manufacturing Sustainability Regulations Rule the WorldThe EU’s Manufacturing Sustainability Regulations Rule the World

The European Union’s environmental regulations for manufacturers have real teeth – and they apply to suppliers that sell into Europe.

Sign up for the Design News Daily newsletter.