Additive manufacturing experts at Rapid + TCT discussed some of the lingering challenges to widespread adoption.

May 26, 2022

Additive manufacturing is poised to transform manufacturing, but the industry is still grappling with a few challenges and a need for ongoing education and collaboration. Experts discussed the industry's advances along with a few ongoing issues in the Rapid + TCT 2022 panel discussions, "AM Challenges that Persist +100 years of Additive Manufacturing Expertise and Insights" and “What Does the Future of AM Look Like?”

There's no doubt that additive manufacturing has come a long way from its early days. "AM Challenges" panelist Jason Jones, PhD, co-founder and CEO of Hybrid Manufacturing Technologies, recalled the need to clean up SLA parts with a manual process years ago. "It was a shock to me—the most advanced manufacturing technology in the world still had manual steps,” he told the audience.

Greg Morris, CEO and co-founder Vertex Manufacturing LLC, shared that "back in the '90s, not only did you have to clean the part, but if you dropped it, it would end up in a thousand different pieces. Materials would be one of the challenges we faced early on in the industry—just the lack of robustness and capability. On the metals side we had the same problem, starting in 2003 when we got involved in the technology—the alloys were much better than what was out there at the time, but they were limited, so we had bronze-based alloys and carbon-steel-based alloys, and we had all kinds of issues when we built parts, whether it was durability or stress cracking or just mechanical properties.”

David Leigh, PhD, chief technology officer for additive manufacturing, 3D Systems Inc., recalled that “CAD software was limited and design tools didn’t allow for organic . . . and we are still dealing with these issues today.”

In terms of barriers persisting today, Leigh explained that “we are looking to do three things with 3D printing. We have already done one—product development steps, getting us to produce products faster by being able to visualize and make prototypes. We’ve adopted that. The second is to replace existing commercial production applications with 3D printing, and the other is to do things that can’t be done any other way but 3D printing. But to be able to replace for end-use parts, either way . . . it’s really qualification of materials. And it’s still very siloed.” Qualified systems, processes, and materials as well as a database for production would help, he said.

Morris agreed that "material qualification is a huge issue" and added that cost is also still an issue. “Until those cost points come down to a certain point, we won’t see as wide acceptance of the technology out in the marketplace,” he said.

The good news is that awareness of additive has definitely grown. "It is getting to a point where almost everyone knows what you are talking about when you say 3D printing or when you talk about leveraging and using the technology," Morris added. "Sitting in 2022, there are hundreds, thousands of applications, compared to 10 years ago, even 5 years ago. So the number of applications are rapidly getting widespread. But costs still haven't come down to a point where it is ubiquitous in almost all manufacturing. That's a world we don't live in today but hopefully soon we'll get to that point."

However, more education is needed. “There are still many companies (tier twos, threes, etc.) whose engineering design departments have not been able to fully appreciate what additive means and can do," Morris said. "So there is still a lot of education yet to happen for a lot of these designers and engineers. It makes sense—they live in their microcosms, and it is very difficult to understand all the different technologies and modalities that exist out there.”

Added Jones: "I remember spending literally 2.5 days prepping a single file to be able print it. I am so relieved I don’t spend that time anymore. But literally we said if we could do this in 3 days it would be good. . . . Thank you to all the software people—3D modeling software has come a long, long ways and I'm thrilled about that.”

Still, “we’ve got a lot of educating to do,” Jones continued. Also, “there is a lack of exposure to really interesting opportunities in a widespread way. . . . The more we can showcase those in front of designers, the more people who will be able to leverage that.” He hopes the industry can "be able to have a wider view, a wider vision, and in parallel, make sure the claims of the technology align to what is possible.”

Leigh advises young engineers to be “generalists.” For instance, “you need to understand controls, materials, and CAD design and post processing . . . Go outside the margins and experiment. . . . Be excellent at one thing but know the context,” he said.

He added that the industry needs to be more collaborative to drive adoption higher. "I think we have the core technologies; I do think we do need to bring costs down and to have better mechanical properties on parts," he said. "And the Internet of Things—being able to connect software to hardware to materials to properties—is a big enabler and I think we are more open to that now and there are several strong software tools that can help enable it.”

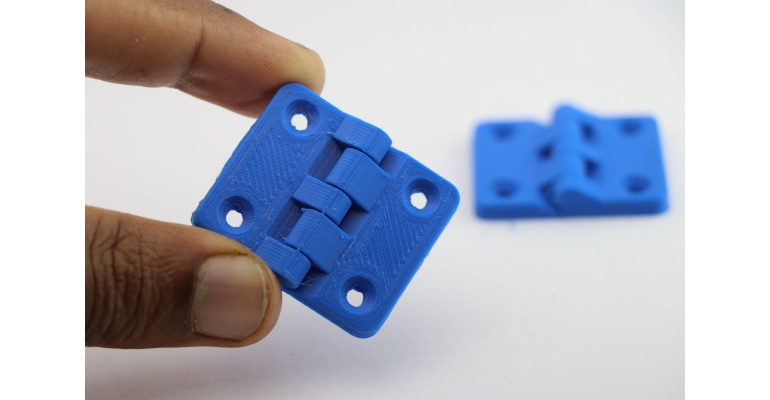

Jones shared future opportunities. For instance, he pointed out that currently the bulk of manufacturing costs is frequently in assembly. “I think the future will be more and more replacement of assembly—that might be part consolidation or multiple types of additive or subtractive or other things that normally would require in intervention being brought together. . . . We are going to see more intelligence embedded in parts—smart design, smart materials, and even hopefully some degree of sensing.”

Cooperation Needed in Additive Manufacturing and Beyond

Speaking in the Rapid + TCT panel discussion, “What Does the Future of AM Look Like?” Lisa D. Block, director, global sales and marketing for Hybrid Manufacturing Technologies, explored the challenge of getting CNC experts and additive manufacturing experts to work together and understand what each is doing.

“I need diverse schools of thought. . . . I need millers. I need guys who know their way around a CNC. I need fresh faces in additive so they can teach the millers how to integrate. . . . It’s very challenging to get the older, more experienced employees and the younger employees on the same page. . . . [I need] a mixture of trying to find very experienced CNC millers who will work with additive,” she said.

About the Author(s)

You May Also Like