3D printed scope has potential use to help prevent heart attacks and disease.

September 14, 2020

Researchers have developed a tiny device that can help doctors get a close look inside blood vessels to help understand afflictions such as heart attack and heart disease to help improve treatment and prevention.

Scientists from the University of Adelaide and the University of Stuttgart developed the device, which is so small that in tests the team could scan the inside of blood vessels of mice.

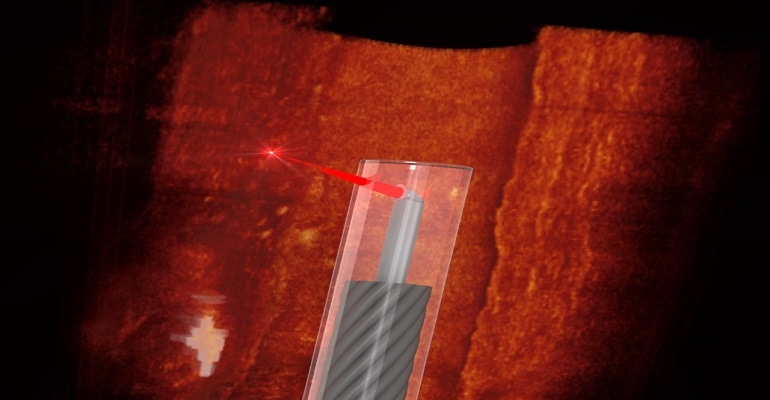

The flexible scope is comprised of a tiny, 3D printed lens that sits on the end of an optical fiber with the thickness of about a human hair.

Researchers hope that by allowing for a close look inside blood vessels using such a scope, they can get a better idea of how much plagues comprised of fats, cholesterol, and other substances that build up on vessel walls and lead to what can be deadly heart ailments, said Jiawen Li, Heart Foundation Postdoctoral Fellow at the Institute for Photonics and Advanced Sensing at the University of Adelaide.

“Preclinical and clinical diagnostics increasingly rely on visualizing the structure of the blood vessels to better understand the disease,” she said.

A Closer Look

Small scopes already are used by doctors to peer inside some of the smallest parts of the human body, but current fabrication methods limit the imaging performance of highly miniaturized probes, researchers reported in a paper in the journal Light: Science & Applications. This has restricted its application.

“To overcome this limitation, we developed a novel ultrathin probe fabrication technique that utilizes 3D microprinting to reliably create side-facing freeform micro-optics…on single-mode fibers,” they wrote. “Using this technique, we built a fully functional ultrathin aberration-corrected optical coherence tomography probe.”

The device is the “smallest freeform 3D imaging probe yet reported,” they wrote.

Indeed, “the entire endoscope, with a protective plastic casing, is less than half a millimeter across,” said Simon Thiele, group leader of Optical Design and Simulation at the University of Stuttgart whose team was responsible for fabricating the tiny lens of the device. The device has a diameter of 0.457 mm, including the catheter sheath.

Device Fabrication

To print the device, researchers used a 450-micrometer length of no-core fiber spliced onto a 20 cm length of single-mode fiber.

“To achieve splicing of this length of no-core fiber, we first spliced a longer section of no-core fiber to a single-mode fiber,” researchers wrote. They then cleaved it to 450 micrometers by 5 micrometers using an automated glass processor with an in-line cleaver.

The beam shaping micro-optic was directly 3D printed onto the distal end of the no-core fiber using a two-photon lithography system, modified with a fiber holder directly attached to the system.

To demonstrate the device’s image quality and mechanical flexibility, researchers imaged atherosclerotic human and mouse arteries.

“The ability to provide microstructural information with the smallest optical coherence tomography catheter opens a gateway for novel minimally invasive applications in disease,” they wrote.

Other collaborators on the project included researchers from The South Australian Health and Medical Research Institute, The Royal Adelaide Hospital, and Monash University.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time, she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like