News out of the RAPID + TCT conference: Stratasys has opened a service center to print human bodies needed for healthcare.

September 15, 2021

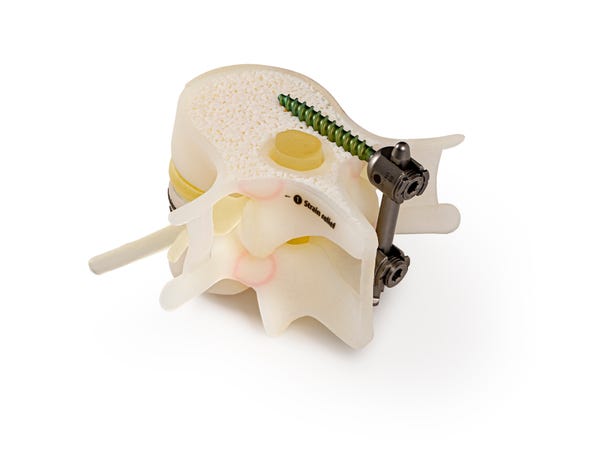

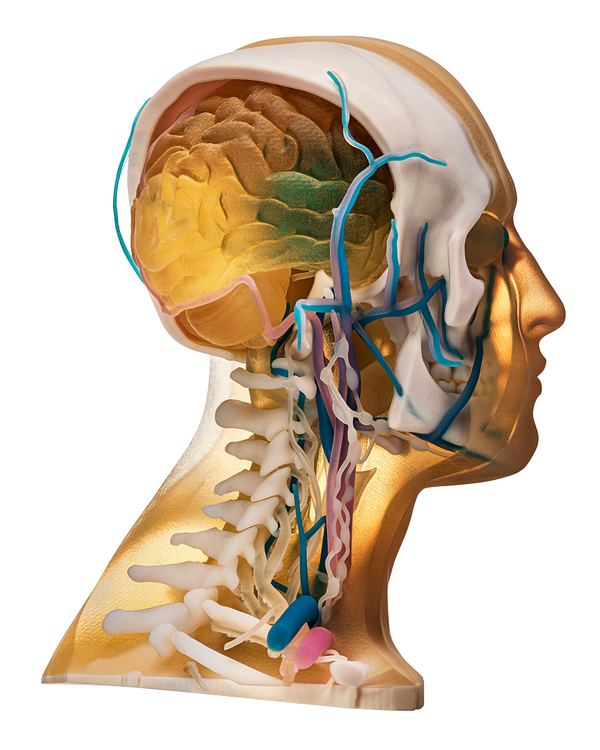

Want a fake body for medical study and surgical practice? It’s called anatomical modeling. These models of the human body are used for product demonstrations, physician surgical training events, and internal product development activities. Traditionally, much of this work was done on cadavers. However, 3D printed models may take the pace of cadavers.

At the RAPID + TCT conference in Chicago, Stratasys announced the Healthcare Print Center in Eden Prairie, Minn. that utilizes Stratasys J750 Digital Anatomy printers. The J750 enables Stratasys Direct to produce life-like, 3D printed medical and dental anatomical models for medical device manufacturers and healthcare providers. “We’re launching a center where we send you the files and print the output on-demand,” said Garrity. “We’ve printed over 1,000 models so far.”

In the first 13 weeks of operation, as part of an invite-only beta service for top medical device manufacturers, Stratasys Direct has already 3D printed over 1,000 models, with each machine running more than 120 hours a week. Stratasys Direct worked with these beta customers to create anatomical models for product demonstrations, physician surgical training events, and internal product development activities.

The J750 Digital Anatomy Printer was designed to produce models that mimic the biomechanical properties of bone, vasculature, and organ tissues. This lets users recreate pathologies not accommodated by cadavers or animals. Healthcare providers and medical device manufacturers can use these models for device testing, medical training, or surgical preparation and consultation.

The printer can create a full replica of the human body. Anatomical modeling began as applications to create smaller specific replicas for parts of the body. “This printer is coming off the back of technology we’ve developed for the digital economy printer to mimic the human body,” Rich Garrity, president Stratasys in the Americas, told Design News. “Printing bones or blood vessels, tissue, skin, the goal is to give that to a surgeon for training or working on a new device.”

Using Models for Surgical Practice

One of the goals of anatomical modeling is to offer a surgeon a replica of the human who will be in the operating room. “These models can potentially cut production time over the use of a cadaver or an animal,” said Garrity. “At the point-of-care, you will be able to pint the person’s anatomy and give the lifelike organ to the surgeon to practice. This saves time in the operating room.”

Part of the value of 3D printed anatomical models is to allow medical professionals to practice an object that mimics the different textures of the body, from skin and fatty tissue to bones and muscles. “The J750 Digital Anatomy Printer can produce models that mimic the biomechanical properties of bone, vasculature, and organ tissues,” said Garrity. “This allows customers to recreate pathologies not accommodated by cadavers or animals.”

Garrity noted that “With the addition of Digital Anatomy printers to Stratasys Direct we can now provide companies with previously limited access to these printing capabilities the ability to utilize Stratasys Direct’s manufacturing services to 3D print anatomical models that meet their exact specifications.”

About the Author(s)

You May Also Like