The two companies partnered to use Resomer polymers in commercial 3D-printed absorbable implants for both soft and hard tissue applications.

March 7, 2023

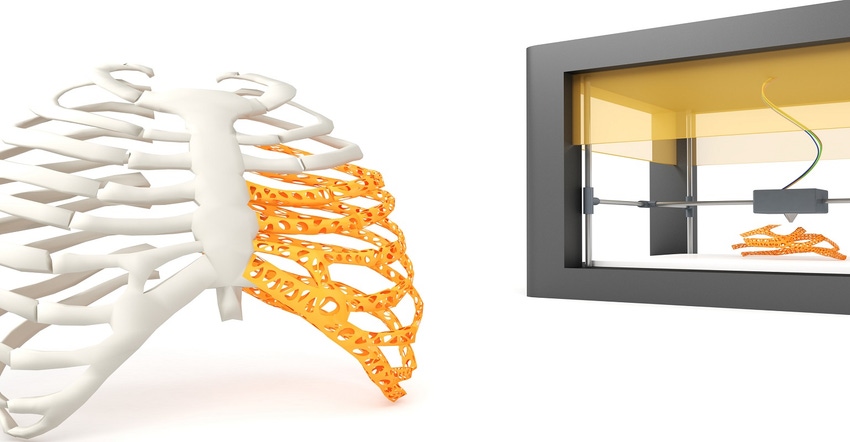

Evonik, a medical materials company, and BellaSeno, a company that makes 3D-printed absorbable scaffolds, have joined forces to commercialize 3D-printed scaffolds for bone regeneration. The bone scaffolds are made with Evonik’s Resomer polymers and are used for large and complex bone defects. The companies started collaborating in 2019 on scaffolds for chest wall and breast reconstruction.

BellaSeno’s custom-made, resorbable bone scaffolds offer a new development in the way bone and soft tissue defects are treated. Their work ensures the correct anatomical positions of tissue grafts. While tissue autographs are considered the gold standard for tissue regeneration, they sometimes lack stability and cannot be packed in a controlled manner. BellaSeno’s 3D-printed tissue scaffolds address this limitation.

The bone scaffolding process:

A Collaborative Move to Improve Patient Outcomes

BellaSeno engaged Evonik for the attributes of the Resomer polymers. “Our philosophy has always been to use safe and clinically-validated polymers of the highest quality and use our engineering know-how to get the target implant properties rather than developing new untested materials,” Mohit Chhaya, CEO of BellaSeno told Design News. “In Evonik, we found the right partner because of the very high standard of material quality. Their spirit of collaboration in helping us develop an optimized manufacturing process as well as the level of flexibility in their polymer compositions allowed us to use them with a variety of additive manufacturing applications and target tissues.”

Evonik saw the partnership as a path to use its materials more effectively to improve patient healing. “We are excited that these scaffolds offer patients superior healing for bone defects. In BellaSeno we have found a like-minded partner, passionate to innovate for better health and well-being,” said Andreas Karau, global head of Medical Device Solutions at Evonik’s Health Care business line.

Resomer is a comprehensive Good Manufacturing Practice portfolio of standard, custom, and specialized bioresorbable polymers used with implantable medical devices. Various special Resomer formulations for 3D printing include filaments and powders to enable customized solutions for a diverse range of applications. “Evonik’s Resomer polymers combine excellent stability and flexibility. These mechanical properties and their degradation profile allow the scaffold to be safely absorbed at a rate that matches the formation of the patient’s own bone,” said Chhaya. “We believe that these novel bone generation implants hold great promise for patients.”

About the Author(s)

You May Also Like