The 3DP industry points to the environmental benefits of reduced inventory, lighter products, reusable materials, and low waste.

September 7, 2022

Experts in the world of academic environmental studies say there is still more research to be done, but several university reports indicate multiple benefits of 3D printing. The sustainability attributes of 3DP come in many flavors:

Less inventory and unused parts with on-demand production

Materials that can be reused or recycled

Less waste compared to machining

Lighter products result in less energy consumption in aerospace and automotive

This quick video sums up many of the sustainable qualities of 3D printing.

We caught up with Guayente Sanmartin, general manager and global head of Commercial Systems & Display Solutions at HP, to discuss her views on the sustainability qualities of 3D printing.

Design News: Do on-demand aftermarket and replacement parts reduce energy consumption?

Guayente Sanmartin: Logistics and warehousing costs are optimized, and downtime is minimized when inventory is stored digitally and parts can be made on-demand and on-site. Digital manufacturing and 3D printing enable flexible design and just-in-time 3D production for virtual inventory that meets the demand for complex parts while reducing costs. In addition, sustainable on-demand 3D production contributes to the reduction of industrial waste and carbon dioxide emissions throughout the product life cycle.

DN: Are there some industries that are particularly well-suited for 3DP sustainability?

Guayente Sanmartin: Yes, automotive. The economic value of small batch productions makes 3D printing a perfect use case for the auto industry where complex or obsolete parts need to be more readily available, even in remote locations. Supporting the production needs of all sizes across industries was the impetus behind the design of our 3D printing technology. It is inherently customizable and always-on, meaning that companies can quickly identify the part in need and design and adapt as needed, and have access to the part blueprint for future needs.

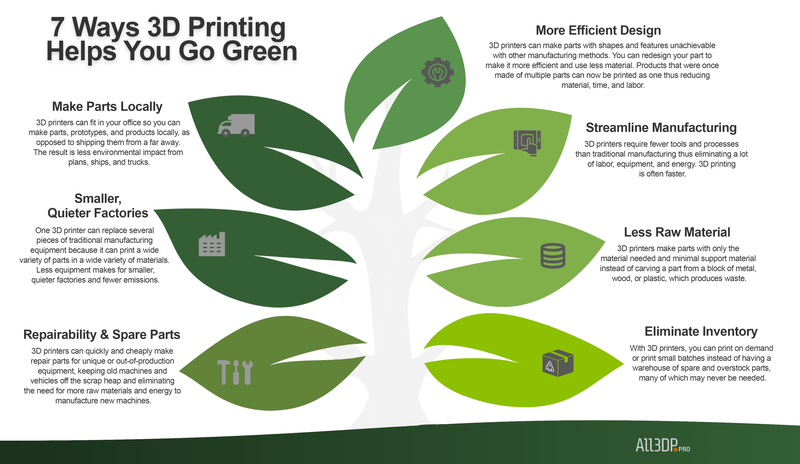

7 Ways 3DP Goes Green

This infographic from All3DP illustrates a number of ways 3DP contributes to sustainability:

DN: Does onsite production offer sustainability benefits?

Guayente Sanmartin: Absolutely. We no longer have to ship parts across the country. Instead, we can ship a file for a part to be produced on-site. This is where reduction in transportation footprint comes into play and helps to supplement the sustainability benefits of 3D printing. In pre-production, 3D printing will dramatically reduce the need for tooling, which requires high quantities of energy to be manufactured.

DN: Does the 3D printing process itself offer sustainable production?

Guayente Sanmartin: HP’s 3D Printing and Digital Manufacturing Center of Excellence in Barcelona is one of the largest and most advanced 3D printing and digital manufacturing research and development centers on earth. The center unites hundreds of experts in what is believed to be the world’s largest population of additive manufacturing specialists in one location. A high level of power is used to ensure the facility operates and, in an effort, to mitigate energy consumption, HP ensured the building was constructed in an eco-friendly way, including photovoltaic panels and other biophilic designs to help monitor the state of the building.

Our vision is to become a fully circular company powered by service models. We are working to reach 75% circularity for products and packaging by 2030. We extend product life through maintenance, upgrades, repair, and innovative service-based business models. At end of service, we strive to reuse or recover all products. We aspire to use 100% renewable energy and achieve zero waste in manufacturing.

About the Author(s)

You May Also Like