December 30, 2015

Last fall we told you about 3D-printed telescope parts -- except, of course, for the mirror. But that may not be true much longer. New telescope mirror designs from NASA for space-based instruments can take almost any shape, and will soon be manufactured using 3D printing. So will NASA's next Mars spacesuit design, along with space structures it's developing with Made In Space.

3D Printed Freeform Optics Mirrors

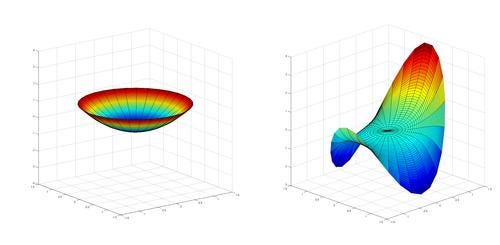

The new freeform optics technology lets telescope mirrors take almost any shape, potentially improving image quality over a larger field of view. It's being made possible by advances in computer-controlled fabrication and testing that allow asymmetrical optics, also known as potato-chip shaped mirrors, as well as better image quality and reduced package size.

NASA optical engineers at the agency's Goddard Space Flight Center are working on the design, integration, and testing of a two-mirror freeform optical telescope for imaging and spectroscopic applications. Engineers there say the technology is promising for developing compact telescopes that will ride along on CubeSats and other small satellites, which are becoming more and more popular as cost-effective alternatives to expensive traditional missions.

Traditional two-mirror telescopes consist of a primary light-gathering mirror plus smaller, secondary mirrors that direct light onto a detector. In these, the round mirrors must be aligned along the system's axis to reduce optical aberrations. But potato-chip mirrors do a better job of correcting for these aberrations and thus provide a larger usable field of view. They also drastically reduce the light path, which is how they make package size smaller.

Next year, the engineers will 3D print a freeform mirror as part of the testing process for the two-mirror instrument. Using a laser melting process, the team will be able to construct a mirror with potentially any shape.

3D-Printed Mars Spacesuit

NASA has also been working on spacesuit technologies that will help astronauts survive in the environment of deep space, with all its challenges of radiation as well as supplies of basics like air and water. The latest suit designs incorporate advancements like regenerable carbon dioxide removal systems and water evaporation systems.

The agency is evaluating several pressurizable space suits for missions to a variety of exploration destinations, including Mars, while keeping in mind the constraints they pose for mobility and fit especially during spacewalks, also known as EVAs (extra-vehicular activities). The current spacesuit standard is the EMU (extravehicular mobility unit), the operational suit used on the International Space Station (ISS).

READ MORE ARTICLES ON 3D PRINTING:

Two new technology demonstrators are the PXS (prototype exploration spacesuit) and the Z-2 suits. Both use 3D printing for at least some of their parts, which help make the suits customizable to different astronaut body sizes and shapes. In the PXS this includes fittings, which also help it adapt to different types of EVAs.

The Z-2, aimed more at planetary surface exploration, represents several firsts, including the first use of 3D human laser scans and 3D-printed hardware for suit development and sizing, the most advanced use of impact-resistant composite structures on a suit's upper and lower torso system, and the most conformal and re-sizeable hard upper torso suit built to date.

3D-Printed Space Structures

Made In Space, the company working with NASA to bring 3D printing into space, made history last year when they sent the first 3D printer to the space station. Now, a company blog says NASA has selected its Archinaut project proposal. The project will develop technologies and subsystems for enabling the first additive manufacturing, aggregation, and assembly of large, complex space structures that don't require extravehicular activities (EVAs) by astronauts.

Not only did Made In Space develop the first 3D printer used in space, it also designed and built the commercially operated Additive Manufacturing Facility, which is scheduled for launch in the first half of 2016. For the Archinaut project, the company's blog says it is partnering with Northrop Grumman, which will provide expertise in electronic interfaces and external thermal control analysis, and Oceaneering Space Systems, which will design and build the manipulator arm.

The blog says Archinaut will result in spacecraft that can "manufacture and assemble unlaunchable structures once on orbit, enabling new mission capabilities such as large antennas and base stations." The project's Phase I will consist of technology demonstrations to determine commercial feasibility.

The project was awarded as one of NASA's new public-private partnerships to advance what it calls "tipping point" emerging space capabilities. "These awards enable us to continue to foster partnerships with the commercial space sector that not only leverage capabilities to meet NASA's strategic goals, but also focus on US industry markets that are at a tipping point for commercialization and infusion," said Steve Jurczyk, associate administrator for Space Technology Mission Directorate, in a press release.

This isn't the first time NASA has explored robotic 3D printing of space structures. We've told you about several the agency has funded, including the SpiderFab project from Tethers Unlimited, which has received two rounds of funding from NASA's Innovative Advanced Concepts (NIAC) program.

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 27 years, covering manufacturing materials & processes, alternative energy, and robotics. In the past, she's also written about machine vision and all kinds of communications.

Like reading Design News? Then have our content delivered to your inbox every day by registering with DesignNews.com and signing up for Design News Daily plus our other e-newsletters. Register here!

Design engineers and professionals, the West Coast's most important design, innovation, and manufacturing event, Pacific Design & Manufacturing, is taking place in Anaheim, Feb. 9-11, 2016. A Design News event, Pacific Design & Manufacturing is your chance to meet qualified suppliers, get hands-on access to the latest technologies, be informed from a world-class conference program, and expand your network. (You might even meet a Design News editor.) Learn more about Pacific Design & Manufacturing here.

About the Author(s)

You May Also Like