DNA, Glass Used to Create Lightweight Material Stronger Than Steel

This unique combination of materials holds promise for new engineering and defense applications.

October 18, 2023

Combining DNA with silica, the base material of glass, has yielded a novel lightweight material stronger than steel, an uncommon combination of materials that could lead to novel engineering and defense applications.

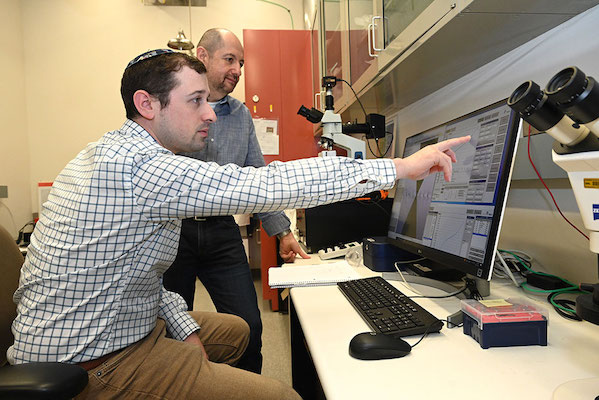

Scientists from Columbia University, University of Connecticut, and the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory collaborated to create a pure form of glass that they coated with specialized pieces of DNA to achieve the new material. Members of the team had worked previously on experiments using DNA structures to build a framework for novel materials based on the behavior of DNA molecules, or nucelotides, they said.

“We focused on using DNA as a programmable nanomaterial to form a complex 3D scaffold, and we wanted to explore how this scaffold will perform mechanically when transferred into more stable solid-state materials," Brookhaven postdoctoral researcher Aaron Michelson said in a post on Brookhaven National Labs's Website.

In biology, DNA, or deoxyribonucleic acid, carries biological information that instructs the cells of organisms on how to form, grow, and reproduce. The material DNA is made of is known as a polymer, a class of tough, elastic materials that includes plastic and rubber with resilience and simplicity that long have inspired the research of material scientists.

DNA as a Foundation For a Material Stronger Than Steel

Nucleotides of DNA bond to each other in a way that allows scientists to develop methods to engineer the folding of the material into specific shapes referred to as "origami," named for the Japanese paper-folding art. These DNA shapes then act as nanoscale building blocks that can be programmed using addressable DNA bonds to self-assemble, meaning that well-defined structures with a repeating pattern can spontaneously form from these origami DNA blocks.

These blocks then cling together to form a larger lattice, or a structure with a repeating pattern, which allows scientists to build 3D-ordered nanomaterials from DNA and integrate inorganic nanoparticles and proteins.

In the current study, the researchers were exploring what they can achieve when that biomolecular scaffolding was to used create silica frameworks that preserve the scaffold architecture. "We explored having this self-assembling material cast in silica, the main ingredient in glass, and its potential," Michelson said.

Researchers also tapped biomineralization—or how certain living tissue produces minerals to become harder—in their fabrication process to create the strength of the resulting material. “We were very interested to explore how we can enhance mechanical properties of regular materials, like glass, but structuring them at the nanoscale,” explained Oleg Gang, a materials scientist at the Center for Functional Nanomaterials (CFN) at Brookhaven Lab and a professor at Columbia University.

Fabricating for Strength

The scientists coated the DNA frames with a very thin layer of silica glass only about 5 nanometers thick. This left inner spaces open to ensure that the resulting material is ultra-light, the researchers said. At the same time, glass on this small a scale is insensitive to flaws or defects, providing a strength that isn’t seen in larger pieces of glass, which can easily develop cracks that can cause them to shatter.

The researchers then applied a technique called nanoindentation, a specialized mechanical test to apply and measure resistive forces, to test the strength of the material. "Our samples are only a few microns thick, about a thousandth of a millimeter, so it's impossible to measure these materials by conventional means," Michelson explained.

Using this method along with analysis with an electron microscope—which allowed the researchers to "simultaneously measure mechanical behavior and observe the process of the compression”—the researchers found the material to be four times stronger than steel though its density is about five times lower, he said.

Researchers published a paper on their work in the journal, Cell Reports Physical Science.

While the work is still in its early stages, the team plans to continue their research by investigating other materials, such as carbide ceramics, that are even stronger than glass to see how they work and behave. This could lead to even stronger lightweight materials in the future.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)