Siemens' Intosite Augments Tecnomatix PLM Platform

August 21, 2014

Manufacturers are increasingly turning to PLM software to manage product lifecycles from inception through design and all the way to the manufacturing process. It's fast becoming an invaluable tool that allows every department to communicate and adjust parameters on the fly without the integration and communication issues that routinely arise with multiple software platforms.

Siemens' Tecnomatix software is one of the leading PLM platforms used by manufacturers such as Ford to get products from fruition to production quickly and efficiently. Already in its 11th iteration, Tecnomatix features the tools that manufacturers need, and it links all the disciplines together for easy dissemination and communication.

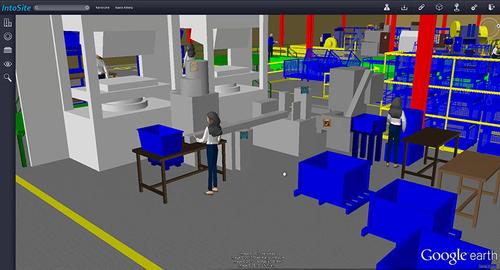

The platform features FactoryCAD that allows users to lay out and plan facilities in 3D using virtual objects, such as machines, overhead conveyors, and even virtual workers (think SIMs), giving critical insight into the layout and installation processes. The platform also features tools such as Factory Flow (GUI for materials flow, frequency and costs), Process Designer (plan the assembly process in a 3D environment), and Process Simulate (simulates everything, including robotic assembly lines, mechanical procedures, and human operations), along with a host of other tools for PLM applications.

To augment its Tecnomatix platform, Siemens recently released its cloud-based location-aware app, Intosite, which lets users navigate a virtual production facility in much the same fashion as traversing through Google Earth. The SaaS application lets users access PLM, IT, and other pertinent information from specific points on the factory floor or at an outdoor location.

For example, the user can get detailed function, maintenance/diagnostics, and production information on a conveyor system just by touching a virtual place mark. Those place marks can offer everything from maintenance reports to videos showing proper handling instructions, along with surrounding information based on the user's relevant location. Users can even create their own visual or text-based tag for those locations, allowing them to upload the data to the Intosite cloud service and share their information with others without using a separate communications application such as email or P2P services. Those tags can point to a host of information, including separate URLs, data sources, or even uploaded files.

Just like Google Earth, Intosite features geographic information systems for knowledge sharing between different locations, allowing others in different departments to access a tag for the relevant data in that area in the same fashion as the indoor place marks. All that information is compiled into layers (think of them like directories with subfolders) that are arranged into categories based on the tags and place marks, so all the data pertinent to that specific area (and subareas) is compiled in one easy location. There is also an advanced search function to help locate company addresses, geographical coordinates, and visual tags for easy navigation.

Ford Motor Company pioneered Intosite for collaboration among its plants all over the globe. These plants deal with many time zones and languages, so Intosite was the perfect collaboration tool to let employees share data and other information with one another with ease.

Essentially, the tool created a forum of sorts that allowed Ford's manufacturing facilities to communicate with one another to improve efficiency and productivity. Ford found that it could handle resolution issues better and reduce travel requirements, which improved productivity.

Suffice it to say that the software is a great tool that can help improve manufacturers' plant operations, and the fact that it works as an addition to Tecnomatix only increases the productivity possibilities. Intosite is available now on iTunes for use with the iPad. It's unclear if it will be made available for Android tablets.

Related posts:

About the Author(s)

You May Also Like