MagicCheck R2 Improves CAD Design Accuracy

August 18, 2014

TransMagic recently released MagicCheck R2, software that improves CAD design accuracy by comparing newly transferred CAD data against the original source to check for input errors. It can read just about every program on the market and provides peace of mind for designers and manufacturers that each design dimension is correct, every time.

If you've ever had the unpleasant experience of having to translate 3D data across various software, you'll know that it's not only a nuisance, but it can also result in the inaccurate transfer of data. TransMagic seeks to change all of that. Its new quality analysis software, MagicCheck, cross-compares all data against the source for accuracy. Never again forget to input the third dimension on a design.

Working with multi-CAD data can be one of the biggest forms of busy work for designers, engineers, and manufacturers. There is no shortage of CAD design software on the market. Oftentimes, organizations that are working together to complete and build a product all use different CAD programs. The result is a team of organizations that must collaborate, but every time a design switches desks, it must be reconfigured to work with the new CAD software. Aside from the process being just about as exciting as watching paint dry, it also leaves lots of room for error. The incorrect transfer of just one dimension ruins the entire design, and when you're designing things like war machines and rockets, you want to make sure those dimensions are right on point. That's why MagicCheck was invented.

MagicCheck is that peace of mind that your design won't completely fall apart due to the incorrect transfer of data. If your structure does crumble, know that it is because your design was... troubled.

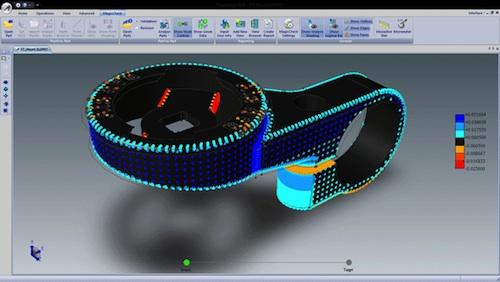

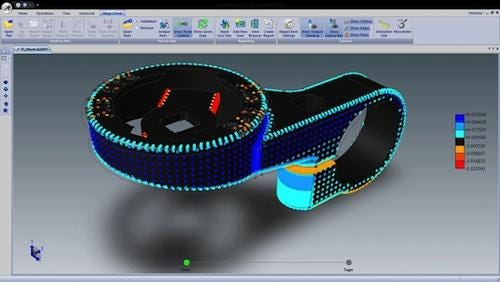

MagicCheck seeks to eliminate all of the problems the CAD design community faces when transferring data. While it does feature multi-body comparison, it also features dynamic dimensioning and three-point move positioning to ensure all dimensions are accurate and realistic. It also allows users to document any changes made by using NC toolpaths and QA inspections. MagicCheck also features tools that allow designers to change the design, without compromising safety.

One of the tools the program features is a three-point move function. This allows a user to change the dimensions of a design in a viable, practical way and will create a report that shows each change that was made, step-by-step. The software also features geometry repair, which highlights heat maps on areas of the design that are out of tolerance, potentially saving companies thousands of dollars on designs that would have never held up from the get-go.

MagicCheck features multi-core processing, which enables the program to inspect, sort, and analyze data quickly; it will also generate reports automatically based on the findings. The program features dockable browser panes, too, which allow users to customize the interface.

MagicCheck performs quality assurance evaluations to ensure designs are in line with Boeing Document D6-51991 and AS9100. It can read CATIA V4/V5/V6, Creo, SolidWorks, Pro/Engineer, NX Unigraphics, Inventor, Parasolid, ACIS, TMR, STEP, IGES, Excel, 3D Point Data, DWG, and JT. It can also write in Excel and HTML.

MagicCheck seeks to change the way Multi-CAD data input is done. The program can save engineering, design, and manufacturing firms both time and money on analyzing the accuracy of data transfer and design safety.

Related posts:

About the Author(s)

You May Also Like