Flexible Supercapacitor Can Be Woven Into Clothing

August 5, 2014

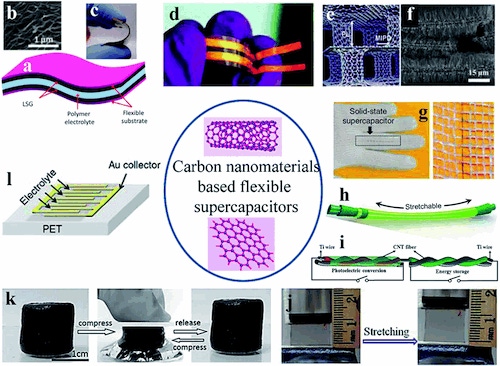

Flexible wearable technology and other small devices may get a leg up in the way they are powered, thanks to an international team of researchers lead by Tao Chen and Liming Dai. The team recently developed a new type of flexible supercapacitor that can be woven into clothing and power everything from wearable medical monitors to communications equipment without bulky battery packs. The fabrication method allows for the supercapacitor to be woven into long fibers (up to 50 feet) while maintaining a charge/discharge rate that outperforms even the best Li-ion batteries.

What is the secret behind this technical marvel? It's none other than our superfriend graphene and its carbon nanotubes sidekick. This combo gives the new supercapacitor its flexibility and high conductivity. To design the supercapacitor, the team used a solution containing acid-oxidized single-walled nanotubes, graphene oxide, and ethelyenediamine that helps "dope" the graphene with nitrogen, which alters the material in its sublattices and tailors it to the application needed (in this case, conductivity and capacity).

The solution is then pumped through a "capillary column" tube and heated in an oven for six hours. Once a fork has been inserted, the sheets of graphene and the aligned, single-walled carbon nanotubes self-assemble into an interconnected porous network, which run the length of the fiber (chemical weaving, if you will).

Pumping the solution through the capillary column makes the material tightly packed and gives it high volumetric energy density (300 Farad per cubic centimeter) that puts Li-ion batteries to shame. All chemistry aside, the team tested the flexible superconductor fibers with 10,000 charge/discharge cycles and found they retain 93% of their performance levels. The supercapcitor's development is still ongoing, and the research team plans to scale up the new technology for low-cost mass production of the fibers to foster commercialization.

Related posts:

About the Author(s)

You May Also Like