Metal 3DP Grows 24% in One Year

The number of metal additive manufacturing systems shipped grew by 24% last year, the 3DP industry itself expanded 11.1% to $20 billion.

April 9, 2024

At a Glance

- Metal additive manufacturing see sharp growth in 2023.

- Emerging metal materials and demand for 3DP parts fuels the growth.

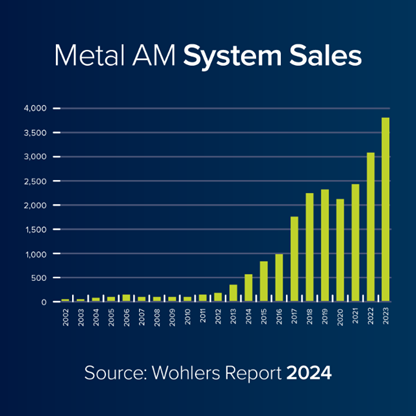

Metal additive manufacturing hit a steep growth spurt in 2023, according to Wohlers Associates, a firm run by ASTM International. In the Wohlers Report 2024, research revealed a 24.4% increase in the shipments of metal 3D printers during 2023. An estimated 3,793 metal AM systems were sold in 2023, compared to 3,049 in 2022. The report also shows an overall additive manufacturing (AM) industry growth of 11.1%, reaching $20.035 for 2023.

Image courtesy of Wohlers Associates

The report has been published for 29 consecutive years. It provides detailed guidance, perspective, and research results on the additive manufacturing AM and 3D printing industry. Wohlers has been tracking metal AM for 21 years.

Wohlers Expects Further Growth

Demand for 3DP metal parts is driving the growth, according to Wohlers. Further growth is expected as costs come down and production speed increases. “Investors, government agencies, and organizations adopting AM are eager to know what will drive growth in the future,” said Terry Wohlers, head of advisory services and market intelligence at Wohlers Associates. “Significant expansion will come from a much wider range of applications and demand for end-use parts. For this to occur, systems will become faster, reducing the production cost per part. A reduction in material pricing, due largely to competitive pressures, will lower costs further,” Wohlers explained.

Materials, Standards and Tech Sharing Spur Growth

Wohlers Report 2024 details how new materials and their qualification will contribute to metal AM, especially in aerospace, defense, healthcare, and energy. The certification of new designs, coupled with industry standards also impacts growth. Wohlers notes that as AM machines and methods of post-processing improve, the industry will see new, robust solutions. These developments will change the equation when determining whether AM is a fit for a production application. Breakeven points—the level at which AM becomes less expensive—will shift from thousands of parts to hundreds of thousands, and even millions for small parts.

The new report was supported by the extensive contribution of information and data from 245 organizations, including service providers, manufacturers of additive manufacturing systems, and third-party material producers. More than 110 people, including 100 experts from 35 countries, contributed to Wohlers Report 2024. The report draws on three decades of data and market intelligence work around the world.

About the Author(s)

You May Also Like