3D Printers That Are Changing the Industry

August 26, 2014

Hackers and engineers everywhere all want to get their hands on a 3D printer. For the past couple years they have been rather expensive and out of reach for most of us. However, as of late, the price of 3D printers has been dropping, while the quality and quantity of printers available has been increasing.

One of the companies paving the way for 3D printing is XYZprinting, which earlier this summer announced the availability of its new line of printers. These include the da Vinci models 1.0, 2.0 duo, and 2.1 duo plus. The da Vinci 1.0 model will only cost a customer $500! The next two models cost $649 and $849, respectively.

The printers ship fully functional and no assembly is required. Furthermore, each printer includes a one-year warranty with a purchase. The software, XYZware, is also free and features a clean and intuitive interface. If there is a disadvantage to the printer, it is that it uses proprietary filament cartridges. Each one is 600g and costs $28. The unique cartridge will make changing the filament quick and easy for users, but will not allow them to use filaments other than the ones provided by XYZ. Each one also has a small amount of Flash memory embedded on the cartridge, which holds information about the filament.

It is clear that XYZ is trying to make 3D printing as accessible as possible to everyone by releasing such a low-priced printer. On the other hand, researchers and tinkerers are still trying to put their own spin on 3D printing by adding useful features. One of the more recent innovations comes from a group of Stanford students.

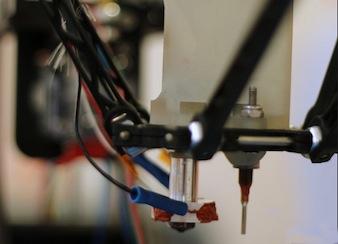

The students have created an attachment for printers, designed to fit onto RepRap extrusion heads. Ultimately, the attachment allows the printer to create conductive paths, which can be used to create circuits. Dubbed the Rabbit Proto, the attachment is a syringe with a 1.37 mm nozzle. Therefore, the printer has the capabilities of laying down electronics during the printing process. The students demonstrated the new attachment by printing a fully functional game controller.

So cute, it brought a tear to my eye; researchers from Carnegie Mellon University and Disney Research Pittsburgh have created a machine that can create fabrics using wool and yarn. The machine utilizes 3D printing techniques to dispense the yarn and knit it together with a needle. First, a digital design is sent to the machine just as with a 3D printer. Then a needle is used to individually drag fibers from the yarn into layers of the design in a method that entangles the fibers together. The researchers also noted the fabric is not as strong as typical materials. Therefore, some type of reinforcement would probably be needed for any prototypes. The researchers have said it can be used to create apparel items and possibly Teddy bears.

Related posts:

About the Author(s)

You May Also Like